704-841-2001

Backed with a massive machinery database considered to be “the blue book” of woodworking machinery), EX-FACTORY Auctions provides a complete assessment of your equipment and allows you to interact with the market real-time in our dynamic Online Auction!

Industry

Woodworking

1908 Results Found

704-841-2001

LOEWER DENIBBING SANDER4-Head, 53" width cap., great Denibbing Sander -- The patented conbination of rollers and rotating / oscillating discs makes the Perfection BBDD sanding machiine the ideal finishing solution for entry doors, cabinet doors, drawer fronts, sheet foods, shutters, face frames, furniture and much nore. -- The LOWER DMBBDD sanding machine is sthe ideal soluton for all sanding applications including whitewood, stain and sealer coats(inciuding UV). The work piece first passes under two large counter rotating spiral hubs, then under eleven rotating discs that oscillate from left to right. This provides very uniform edge breading in whitewood sanding and eliminates most (if not all) hand sanding of the sealer coat. -- The patented combination of roller and rotating discs provieds very uniform sanding across the entire work piece, even into deep profiles without loosing detail. -- SPECIFICATIONS OF MACHINE --Thickness of work piece Min: 10mm (1/2")-- Max: 80mm (3") --Feed belt width Max:1350mm (53") --Feed belt motor 1.5 KW (3Hp) 3-15 M/min (10-50 Ft/min) --Top sanding roller 2.2KW (3Hp) 25-300 O/min (RPM) --Disc Rotation 2.2KW (3Hp) 25-300 O/min (RPM) --Disc Osciliatiojn ).37KW (0.5) 10-60 O/min (RPM) --Vacuum motor 7.5KW (10Hp) --Machine weight 1,800 kg -- Aproximate Machine dimensions based on similr machine W:2000mm (6'7")/ L:2780mm (9'2")/ H:6'11")

Dust Collection Pipe (Snap Ring type Pipe)Quantity - Diameter - Length Description(2) 22" - 12" - 38" Branch.(1) 24" - 12" - 38" Branch.Many loose Snap Rings in tote.(1) 25" - 59" Pipe.(4) 22" - 59" Pipe.(2) 24" - 59" Pipe.(1) 24" x 22" x 6" 21"; Reducer with branch.(1) 22" x 20" x 12" 33"; Reducer with branch.(1) 11" x 10" x 10" 29"; Reducer with branch.(1) 12" Auto gate.(18) 10" - 59" Pipe.(2) 9" - 59" Pipe.(1) 11" - 59" Pipe.(4) 12" - 59" Pipe.(1) 22" - 29" Pipe.(1) 20" - 50" Elbow.(1) 20" x 16" x 12" - 33" Reducer with branch.(1) 24" x 24" x 10" - 29" Branch.(1) 24" x 24" x 6" - 24" Branch.(1) 16" x 12" x 7" x 7" - 45" Reducer with branch.(1) 22" x 22" x 6" - 20" Branch.(7) 12" - 59" Pipe.(4) 14" - 59" Pipe.(1) 16" - 43" Pipe adj.(18) 8" - 59" Pipe.(68) 6" - 59" Pipe.(10) 3" - 59" Pipe.(2) 8" - 32" Pipe.(32) 8", 9", 10", 11" - 59" Pipe.(46) 5" - 59" Pipe.(8) 7" - 59" Pipe.(39) 4" - 59" Pipe.(1) 14" x 12" x 6" - 21" Reducer & branch.(1) 14" x 14" x 6" - 21" Branch.(20) 3", 4", 5", 6" - Various pipe.(1) 6" x 6" x 6" - 21" Branch.(1) 10" x 10" x 4" - 17" Reducer.(1) 10" x 7" x 7" - 23" Reducer.(1) 10" x 9" x 4" - 17" Reducer & branch.(1) 10" x 7" x 7" - 23" Reducer & branch.(1) 10" x 7" 9" Reducer(5) 10" - 18" 90° Elbows.(20) 5" - 8" 90° Elbows.(7) 7" - 8" 90° Elbows.(23) 6" - 8" 90° Elbows.(20) 8" - 20" 90° Elbows(4) 5" - 6" Saddle.(1) 7" x 4" x 4" - 19" Reducer & branch.(2) 8" x 7" x 6" - 21" Reducer & branch.(1) 7" x 6" x 4" - 17" Reducer & branch.(1) 11" x 11" x 9" - 31" Branch.(1) 12" x 8" x 8" - 19" Reducer & branch.(1) 7" x 6" x 5" - 19" Reducer & branch.(1) 11" x 10" x 4" - 17" Reducer & branch.(1) 14" - 39" - 90° Elbows.(1) 9" - 20" 90° Elbows.(2) 10" - 16" 90° Elbows.(1) 7" 22" Pipe.(1) 10" x 10" x 4" - 17" Branch.(2) 10" x 8" x 6" - 21" Reducer & branch.(1) 14" - 39" 90° Elbow.(1) 9" - 20" 90° Elbow.(2) 10" - 16" 90° Elbows.(1) 7" - 22" Pipe.(1) 10" x 10" x 4" - 17" Branch.(2) 10" x 8" x 6" - 21" Reducer & branch.(1) 8" x 8" x 6" - 23" Branch.(1) 12" x 10" x 6' - 21" Reducer & branch.(1) 8" x 6" x 4" - 18" Reducer & branch.(28) 4", 5", 6", 7", 8", 9", 10", 14" Misc.(1) 14" x 11" x 6", 6" 42" Reducer & branches.(1) 8" x 7" x 6" - 21" Reducer & branch.(1) 12" x 7" x 7" - 34" Reducer & branch.(1) 12" x 11" x 4" - 17" Reducer & branch.(1) 5" x 5" x 5" - 17" Branch.(1) Batch 50' - 24" Straight pipe.(1) Batch various 24" 90° elbow.(1) Batch various 24" - 45° elbow.(1) Batch 150' - 12" Straight pipe.(1) Batch various 12" various fitting.

Call for Price

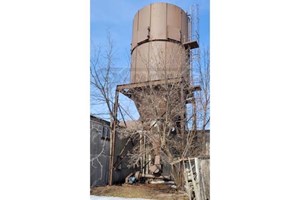

MAC/SCHENCK 144-RPT-252 STYLE III Baghouse Filter System with Pulse Jet Cleaning and Rotary Air Lock (RAL) discharge.RPT Filters (Rectangular Pulse Top-Removal) Rectangular top removal bodied filter unit designed to handle high air volumes. • Bags are removed vertically from the top clean section. Walk-in plenum so the filter media replacement and maintenance can occur in an enclosure for inclimate weather. -- Baghouse Capacity: 4,770 sq. ft. of cloth consisting of (252) bags, 144" long 16 Oz P84 Top Load bags and bright wire cages. Depending on your application, for example at an air-to-cloth ratio of 3.14:1 it can develop 15,000 CFM. -- Equipped with: (1) PHELPS FAN, Material Handling, WRM-380 CCW-TAU HD ARR. 8 with A-36 inlet flange Performance at 15,000 ACFM & 15" SPWG, 1780 RPM, 315°F, 0.050 #/cu. ft..500' elev. Direct drive MOTOR IS NOT INCLUDED but was designed for 75 HP, 1800 RPM,, 365T. Fan was connected in a negative pressure configuration, flanged inlet & outlet. -- Bag Cleaning; Requires 33 SCFM of clean, dry air at 90-100 PSIG. -- Complete with: Auger on bottom of hopper feeding Rotary Air Lock (RAL) with approx. 1.5 HP gearmotor at 22 RPM.; (3) Rupture style explosion vents.. -- Features: Equipped for High Temperature (400°F) bags Special equipment includes VITON Diaphragm valves, copper line (in lieu of polyflo tubing)high temperature air header connections and hi-temp purge pipe compression on couplings. (2) 2" NPT couplings with plugs are included in the plenum section for future addition of sprinkler/deluge system. -- Filter unit constructed of carbon steel containment with 3/8" x 4" reinforcing ribs. 34" diam. high entry inlet and top outlet. -- Includes: Nema 4 Timer Board and solenoid valve enclosure. Each require 110/60 Hz power supply. Filter has (2) solenoid valve enclosures. -- Dimensions: 492" overall height (ground to top), 156" square sides. Separates into (3) sections: Top Plenum, filter section and bottom hopper/support steel. -- Dismantling/rigging is included. Please inquire for transport to your location.. -- NOTE: Extra high Stainless Steel stack is available if you want it.

Call for Price

MAC 120-MCF-572 High Capacity Baghouse Dust Collection system with Rotary Air Lock (RAL) and Medium-pressure Controlled air cleaning dust Filter (MCF). -- Baghouse Capacity: 50,000 CFM @ 7.2:1 Air-to-cloth ratio (ACR), approx. 6,921 sq-ft of filter area based on (572) Filter bags; 120" long x 5" dia. -- Equipped with: (1) AIR TECH size 402, BISW, Backward Inclined Air Handling Fan, Class IV, with 40" inlet, ground-mounted on unitary base, flanged inlet box & outlet. For prior application fan operating point (RPM/SP) is set up for about 41,526 CFM @ 12" WG at 1566 RPM, drawing 119 BHP. the fan is equipped with a variable volume damper on discharge. Fan range is about 40,000 - 55,000 CFM. Powered by a TOSHIBA 150 HP TEFC, 444T, 1800 RPM motor packaged with a belt drive -- Bag Cleaning: Mac "Never-Miss" Cleaning System with rotating arm, diaphragm valve for pulse cleaning Approx. 3 HP positive displacement (PD) pump for bag cleaning at only 7- 9 PSIG. 1 HP direct drive gear motor for distribution arm, integral manifold/surge tank, pneumatically controlled firing mechanism activating the diaphragm valves/nozzles. When cleaning arm & bag segments are correctly aligned air nozzles fire directly into bags without wasted cleaning air. -- Includes: MAC FS24x24 AIRLOCK Rotary Air Lock (RAL) with approx. 2 HP SYNCROGEAR MODULE gear motor; sprinkler package; 60° Cone-shaped hopper attached to MAC at bottom of cone. -- Features: Floor-standing Electrical controls (excluding shared controls) with MOTORTRONICS Solid State AC Softstart for main 150 HP motor. -- Additional Features: Explosion vents. Summer/Winter diverter and return air ductwork. Support structure. Caged access ladder from ground Service Platform and to the top plenum. -- Baghouse constructed of 7 gauge carbon steel containment; one piece body all welded construction, 180" (15') diameter shell panelized unit, walk-in plenum for maintenance and bag replacement. -- MAC design features: MCF 4HVP Pump package. MCF Medium-pressure air requires less HP and yet offers high dust and air collecting efficiency with unmatched baghouse cleaning at lower operating cost. MCF pulses each bag the same number of times with the same amount of air. (Unlike some competitors which clean the inside rows of bags more often than necessary thus wasting energy, causes uneven pressure drop, and bag wear). -- (2) of these identical units are installed per photos, one only is available based on Owner/buyer agreement and price point. Material handling fan/drive is not included and is assumed to stay with the remaining filter unit. -- Overall dimensions: 580.5" high x178.5" square frame with an estimated weight of filter unit (less structure and accessories) 31,000 Lbs. -- Professional dismantling/rigging, truck loading and transportation are available at extra cost. -- NOTE: Per photo #1 on the Ex-Factory website the unit for sale is on the right-hand side. The left-hand unit is not easily accessible.

Call for Price

MACDONALD STEEL 37 PTFU Dust Collector with Shaker type bag cleaning. -- 30,500 CFM, 150 HP blower with 37" inlet dia., 4,354 square feet of cloth filter area with 7.0 to 1 air to cloth ratio, (114) 9" dia. X 168" (14') long bags, 1.5 HP shaker motor, -- MACDONALD 37 AT main fan belt driven by a 150 HP WEG motor. Silencer on fan discharge. 11' dia. baghouse with 2,160 cubic feet storage cap; overall height of approx. 55' -- Includes: Retrofitted hopper with transition to bottom auger to Rotary Air Lock (RAL). Explosion Doors -- Features: Enclosure with SIEMENS Variable Frequency Drive (VFD) for efficient ramp-up control convenient fan speed control as needed.Summer/Winter diverter on return air line. Truck level loading .'Y' branch on inlet with approx. 33" & 16" supply lines. -- Complete with: Electrical control panels with with starters for auger and RAL. All external ducting, and about 100' manifold of 33" dia. steel flanged main trunk supply line. Safety ladders & access platforms.

Call for Price

MACDONALD STEEL 65 ST Dust Collector System with Shaker filter cleaning, Rotary Air Lock, and 18' dia. housing. -- Specifications: Capacity for 65,000 CFM, 18' dia. shell, with 8,199 sq-ft. of filter area for an air-to-cloth ratio of 7.7:1. T-150 polyester bags 14 oz. with a 30 - 40 CFM.@ 1/2" WG permeability. -- Current Fan configuration: System 1: Fan inlet of 33" at 32,500 CFM; System 2: .Future capacity for a second fan as per System 1. Return air duct is 42" x 72". -- Filter Cleaning: Top mounted electrically operated & timed mechanical shaker, approx. 2 HP motor which will automatically operate on all shutdowns. -- Equipped with: MACDONALD 18" Rotary Air Lock (RAL) with bottom eductor/T-section for connection to a relay/transfer fan (not included.). -- Complete with Fire Damper, Summer/Winter Damper with Silencer, Explosion doors, safety ladders, and access platform. -- Features: 13" MH/HT 20 HP Transfer/Transport fan -- Overall height is currently 57'-3" with 12' clearance under RAL. Weight of filter with structural steel is 29,000 Lbs plus fan is about 3,000 Lbs. -- Shell panelized construction (made of separable panels allowing for road/Hwy travel).Professional rigging, loading and transportation are available at extra cost; quote upon request.

Call for Price

MACDONAL STEEL - 26 PT: Dust Collector with RAL/Auger and Diverter Gate.Overall data: 16,700 CFM; 1,780 sq/ft. of cloth area comprised of: (85) Bags: 8" Dia. & 120" long; 60 HP blower; 26" inlet dia. with retrofitted Auger/Rotary Air Lock. -- Equipped with: Electrically operated mechanical bag shaker; back pressure damper on inlet manifold; Diverter/Abort Gate. -- Complete with: Safety hoop access ladder; (1) access platform to filter media; (1) top mounted fan/motor; silencer on return air. -- Starter/electrical control panels and disconnects inside/outside for each drive. -- Used 150 HP; rated VFD is available at extra cost.

Call for Price

MACHINEX - SRM-1: SamurAI Sorting RobotThe SamurAI is a 4 articulation Robot, which: Targets designated products to capture, maneuver, and deposit into the respective chutes.Includes: Unique integrated Suction System driven by a blower, enabling the removal of small and light particles (such as plastic film) into a dedicated Cyclone and lowering compressed air requirements .Specifications: -- Up to (70) picks per minute (nearly double the average pick rate (30 - 40) picks/minute) of a human sorter. -- Up to 95% efficiency of targeted product recognitionEquipped with: -- (1) Sorting Camera. -- (2) Sorting Arms. -- HMI Interface and controls. -- Currently over a 32" W Conveyor. -- Adaptive Concept: Designed for multiple robot configurations and extended conveyor width options. -- Material handling flexibility: Recovered products handled through fixed sorting chutes or portable bins -- Lighting encapsulation: For optimal product recognition in all possible sorting environments. -- Ergonomically designed: Maximize productivity by easy access for preventative maintenance. -- Temporary manual sorter replacement. -- Safe working environment with easy access inside the machine for a sorter to replace the robot during planned maintenance shutdowns.Positively: Extracts recyclable commodities from a specific stream of material (e.g.: plastics, fiber or metals from a reject line); Negatively: Sort a dedicated stream from all its contamination (e.g.: PET quality control after an optical unit).Prepping machine and loading on your truck is included.

$79,500

MACMAZZA TS 90 FRONT LOAD, AUTO. PANEL SAW: -- Specifications: -- 169" Cutting length; 2.83 effective cutting height, 12 HP main saw motor. -- Features: -- Variable saw carriage travel speed 3 - 328 FPM, constant return of 328 FPM; electronically controlled overhead program fence, rack & pinion driven on both sides, forward & return speed 2 - 164 FPM, equipped with (6) clamps. -- PC-Based LENOVO 90GA computer control with CELERON Quad-Core J3455 Processor & 19" color monitor, 4 GB RAM, 1,000 GB Hard drive, (6) USB Ports. -- Complete with: -- Rear table constructed of aluminum profiles with plastic rollers, (3) front air floatation tables; side pressure device for crosscutting on pressure beam.Photos not of actual machine.

$23,500

MAGGI GT 800 CNC MACHINING CENTER: -- SpecificationsFlexible "Vertical/Horizontal" Boring & Grooving Machining Center that can reach movement speeds of: 82 FPM (25 MPM) in "X" & "Y" axis & 49 FPM (15 MPM) in "Z" axis with total safety. -- Working FieldMax. part size for "X" axis is virtually infinite; "Y" axis 31.5" (800 mm); max. part thickness 2" (50 mm). Min. part size for "X" axis is 9.84" (250 mm); "Y" axis 3.93" (100 mm); min. part thickness of 0.39" (10 mm).Panel End/Edge Reader for perfect panel positioning/placement. -- Boring Unit:Suitable for drilling on face & sides of panels including: Holes for dowels, hinges, KD fittings, and shelf holes.(1) Boring block with: 3 HP (2.2 kW) - 3,400 RPM Motor; (7) vertical spindles with: (4) Spindles in "X" axis & (3) spindles in "Y" axis.(1) Horizontal spindles with: (1 + 1) In "X" axis for top & bottom edge boring.(1) "X" Axis grooving saw: 5,000 RPM; Max 100 mm saw blade diameter.Boring Capacity: 0 to 800 mm (31-1/2") with any spindle. -- Operator & Machine ControlPC Front End with: Extremely intuitive user interface with up to (1,000) program storage space; real-time multitask processing.12" TFT "Touchscreen "Monitor; soft touch keypad & industrial mouse; RS-232 Serial ports, USB ports; (1) CD ROM drive. -- Complete with:Pneumatic part clamping roller devices; auto lubrication system; sound enclosure & safety devices. -- Actual Model is: MAGGI GT 800

MAGGI SYSTEM 23 Construction Hole Boring Machine Adjustable 23-spindle boring head on 32 mm centersSpecifications: -- Stops in 0° & 90° with pneumatic positioning in vertical & horizontal. -- 0" - 2-1/2" Adjustable drilling depth with patented setting device. -- (2) Patented material clamps with auto-setting & safety feature. -- Head height fine adjustment with a mechanical digital readout. -- 2 HP - 2,800 RPM Motor. -- 38" x 16" Table with mechanical digital side fences for mirror-image. -- 120" Line Boring fence with (4) repeat stops & spring loaded repeat pin. -- Foot actuated pneumatic clamps & drill cycle. -- Magnetic starter, overload protection and (1) set of "quick change" chucks. -- Dust Outlet: 3".Net weight: 630 Lbs; Dimensions: 51.7" x 37.8" x 50" Tall; Crated Dimensions: 44" x 38" x 42" Tall; Crated Weight: 664 lbs.Available in single phase ... Add $ 600.00

MAGGI SYSTEM 29 CONSTRUCTION/LINE BORERAdjustable 29-spindle boring head on 32 mm centers with position indicator. -- Stops in 0° & 90° with pneumatic positioning in vertical & horizontal. -- 0" - 2-1/2" Adjustable drilling depth with patented setting device. -- (2) Patented material clamps with auto-setting & safety feature. -- Head height fine adjustment with mechanical digital readout. -- 2 HP - 2,800 RPM Motor. -- 45" x 16" Table with mechanical digital side fences for mirror-image. -- 120" Line boring fence with (4) repeat stops & spring loaded repeat pin. -- Foot actuated pneumatic clamps & drill cycle. -- Magnetic starter, overload protection and (1) set of "quick change" chucks. -- Other Accessories also Available!

MAGGI SYSTEM 46 Double Head Line Boring Machine:Heavy Double Head Line Borer with (2) 23-spindle heads; 32 mm spindle spacing.Specifications: -- Drilling from the bottom up and with 5-1/8" - 25-19/32" distance between rows. -- Drilling vertically from the bottom allows the chips to drop down falling out of the holes. -- Drilling depth of up to 2-1/16" (55 mm) max., takes only seconds to set. -- (2) 2 HP - 3,500 RPM Commercial Duty motors; spindles with steel gears & high quality bearings. -- Easy repetition by (2) air index pins for continuous line drilling, left and right roller track supports extend up to 400 mm (15-3/4") for larger panels.Features and Includes: -- 120" Back fence with (4) repeat "flip" stops; includes 27-3/4" (704 mm) fence for quick positioning of flip stops. -- (6) Pneumatic holddowns to automatically actuate when the drill cycle begins. -- (46) "Quick Change" chucks for easy tool change. -- Magnetic motor controls and 1/4" air regulator with filter and oiler; 100 PSI required air pressure.

MAGGI SYSTEM 21 PRESTIGE Construction & Line BorerAdjustable 21-spindle boring head on 32 mm centers with position indicator.Specifications: -- Stops in 0° and 90° with pneumatic positioning in vertical & horizontal. -- 0" - 2-1/2" Adjustable drilling depth with patented setting device. -- (2) Patented material clamps with auto-setting & safety feature. -- Head height fine adjustment with magnifying glass viewer. -- 2 HP - 2,800 RPM Motor. -- 34" x 15" Table with mechanical digital side fences for mirror-image. -- 120" Line Boring fence with (2) repeat stops. -- Foot actuated pneumatic clamps & drill cycle. -- Magnetic starter, overload protection and (1) set of "quick change" chucks.OPTIONAL: -- 230V Single Phase add $600.00 --29900100 Stop Reference Pin for Line Boring $195.00 -- 26000069 Set of Reference Fences for 45 and 90 degrees $195.00 -- 36000061 Additional Quick Change Bit Adaptor $27.50 ea -- 29971019 Additional Holddown Cylinder Assembly $395.00 ea -- Hinge Boring Head (Specify Blum, Grass, Salice, or Hettich) $695.00 -- TDBSE5705LH or RH 5mm x 57mm LH OR RH Brad Point $9.85 ea -- TDBSE5708LH or RH 8mm x 57mm LH OR RH Brad Point $11.95 ea -- TDBSEHB5735LH or RH 35mm x 57mm LH OR RH Hinge Point $26.80 ea -- FREIGHT TO ANYWHERE IN THE CONTINENTAL USA $ 300.00

MAGGI SYSTEM 35 CONSTRUCTION/LINE BORINGAdjustable 35-spindle boring head on 32 mm centers with position indicator. -- Stops in 0° & 90° with pneumatic positioning in vertical & horizontal. -- 0" - 2-1/2" Adjustable drilling depth with patented setting device. -- (2) Patented material clamps with auto-setting & safety feature. -- Head height fine adjustment with mechanical digital readout. -- 2 HP - 2,800 RPM Motor. -- 45" x 16" Table with mechanical digital side fences for mirror-image. -- 120" Line boring fence with (4) repeat stops & spring loaded repeat pin. -- Foot actuated pneumatic clamps & drill cycle. -- Magnetic starter, overload protection and (1) set of "quick change" chucks. -- Other Accessories also Available!

Call for Price

MAKITA LS1013 10" Double Bevel Sliding Compound Miter Saw, with Stand Specifications: Miter angles 52° Right & 47° Left, with (9) Positive stops at 15°, 22.5°, 31.6°, & 45° Left or Right & 0°. Bevel angles 45° Right & 45° Left. Dimensional lumber cut capacity: 2" x 12" at 90° & 2" x 18" at 45° Left. Arbor dia. 5/8" Equipped with: 1,430 W - 13 A - 3,700 RPM Motor, with Electric brake. Complete with: DELTA "55-155" Universal Miter Saw Stand. Machine with Stand Dimensions: 104" x 28" x 59" H. Machine Dimensions: 30" x 28" x 25" H. Machine Weight: 50 Lbs. Stand Dimensions: 104" x 22" x 35" H. Stand Weight: 85 Lbs.

$89,000

MAKOR Q-ONE 1300 FEED THRU FLAT LINE SPRAY SYSTEM: -- Features:The Q-ONE sprayer is a single-arm Reciprocating System with paper belt overspray collection; it combines productivity, flexibility, and quick change-over with a limited investment. This continuous belt conveyor system, combined with disposable paper promotes a "self-cleaning" machine & dramatically reduces clean-up & service time.Operation: -- Suitable for all types of conventional coatings from solvent to water-based materials; -- Conveyor advances only when parts are present. -- Conveyor system with a vacuum belt to secure & support the feeding of the disposable paper, ensuring proper tracking & automatic winding of the paper roll. -- The paper roll change-over time is only a few minutes. The panel lies flat on the belt which prevents the transfer of over-spray onto the bottom side. -- The spraying enclosure is pressurized via (2) intake fans and filtered by means of dry filters. -- This system allows clean air & maintains consistent airflow throughout the Spray Cabin, also limiting the machine maintenance time to a minimum and produces an enhanced quality finish, control & containment of over-spray, resulting in significant material economy. Internal airflow is adjustable by means of inverters. -- The spray system uses an inverter drive, variable speed reciprocating trolley which provides a consistent spray speed & pattern across the entire conveyor belt.Equipped With: -- Spray system for (4) spray guns (guns NOT included), mounted on a "Quick-Change" gun support trolley. -- (2) Gun holding plates with "QC" (quick-change) system to allow for fast gun replacement -- (3) High-pressure Coating Circuits with recycling through a fluid distribution manifold + (1) High Pressure Circut (without return) for Solvent. -- Recycling Coating Circuts have return hoses for quick washing the Circut & recirculating of the Coatings. -- PLC touch-screen for clear visual operator interface & large memory storage of working programs, parameters, controls & diagnostic functions. Photodiode light bar reads the location and size of the part to be sprayed. Technical Specifications: -- Working Length: infinite -- Working Width: 25 - 1,300 mm (1" - 51") -- Working Height: 3 - 60 mm (0.125" - 2.375") -- Feed Motor: 0.75 kW, variable speed control from 1 - 6 MPM (3.3 - 19.6 FPM) -- Vacuum Belt Motor: 1.5 kW (2 HP) -- Paper Rewind Motor: 0.18 kW 0.24 HP). -- Paper Roll: Dia. 550 mm (21.6") max. -- Reciprocator Motor: 2.2 kW -- Exhaust Fan Motor: 5.5 kW -- Air Flow: 7,950 CFM -- Pressurization Air: 2 x 3,900 CFM -- Total Installed Power: 13 kWNOTE: Pumps & Spray Guns are NOT included with this system.

Call for Price

MURPHY-RODGERS MRJ-610-122 Pulse Jet Dust Collector with Rotary Air Lock and Transfer Fan.Specifications: -- 8,500 CFM approx. @ 9 to 1 air to cloth ratio baghouse dust collector with (60) 10-feet long filters; total cloth area of 943 sq. ft. -- Filter Cleaning: Continuous Self-cleaning Using Compressed Air. -- Main Fan: 30 HP top-mounted blower motor. with approx 18" dia. inlet. --System includes: Relay/Transfer fan, steel structure support stand, low height as waste is transferred by fan, safety ladder/platform, top safety railing, and approx. 16" Rotary Air Lock.Actual model is MRJ 610 -122.

$41,500

NANXING NCG 2512L CNC FLAT TABLE MACHINE (W/LOADING/UNLOADING) + Auto Label Printing Application: -- Specifications:Bridge Gantry with 4' x 8' "Matrix" grid Phenolic surface table for "Nested Base Manufacturing", Automatic Loading and Unloading System with Vacuum cups & Sweeping Arm.Loading flow from Left to Right configuration. -- Work area:"Matrix" grid Phenolic surface flat table designed for "Nested Base Manufacturing". -- Working cap.:"X" Axis is 98.4" (2,500 mm), "Y" axis is 48" (1,220 mm) & "Z" axis is 9.8" (155 mm);Max. programmable speed: "X" & "Y" Axis 98 FPM (30 MPM), "Z" axis 65 FPM (20 MPM). -- Boring Unit:(10) Independent vertical boring spindles with (5) spindles in "X" axis & (5) spindles in "Y" axis, for 10 mm tools max dia. and 35 mm max. bore and 32 mm OC; -- Machining:(1) 12 HP (9 kW) Vertically mounted HSD electro-spindle router with HSK-63F adapters, Inverter controlled variable spindle speed up to 24,000 RPM, with max. torque from 12,000 RPM.(1) 8-Position Automatic tool changer with "revolver type" ATC tool plate. -- Operator & Machine Control: "SYNTEC" Controller, English language cutting/optimizing software, MS-Windows "10" based technology,32-bit Pentium - 400 MHz processor (w/operating system for Windows 7), 4 GB hard drive,15" Dell, international keyboard, soft-touch keypad & industrial mouse and USB port. -- Complete with:(2) 7.5 HP (5.5 kW) air-cooled vacuum pumps that provide 5,650 cu.ft./hr. (160 m3/hr.) of suction power: Safety & Emergency stops: Automatic lubrication system for guides & ball screw: Auto-Transformer for voltages between 200-600 V: -- Options Include: (1) NC Controlled infeed Scissor Lift table with vacuum loading Automatic Label Printing Station with Automatic Material Alignment (1) Rake system (1) NC controlled & powered flat belt outfeed table with vacuum sweeping system Tool Touch-Off Probe with automatic program update according to the tool length. Actual Model is NANXING NCG 2512L

$7,700

NASH 50-72 Spindle Sander(10) Spindles, 72" chucking cap., 3/8" - 6" dia. range;Specifications: -- 2-1/4" Dia. main arbor with long keys for driving head & tailstock wheels. -- Variable spindle speeds from 700 - 3,000 RPM, 7.5 HP spindle motor, 2 HP feed & oscillation rack motor, variable oscillating speed (60 - 120) strokes/Min, oscillating stroke adjustable up to 2" in length. -- (5) 72" Sanding racks, self-adjusting & oscillating. -- Equipped with: Overhead mounted dust hood, push-button control panel; production rate of (10 - 30) pieces/Min. -- Includes: brushes and sandpaper