704-841-2001

Backed with a massive machinery database considered to be “the blue book” of woodworking machinery), EX-FACTORY Auctions provides a complete assessment of your equipment and allows you to interact with the market real-time in our dynamic Online Auction!

2086 Results Found

704-841-2001

LOEWER DENIBBING SANDER4-Head, 53" width cap., great Denibbing Sander -- The patented conbination of rollers and rotating / oscillating discs makes the Perfection BBDD sanding machiine the ideal finishing solution for entry doors, cabinet doors, drawer fronts, sheet foods, shutters, face frames, furniture and much nore. -- The LOWER DMBBDD sanding machine is sthe ideal soluton for all sanding applications including whitewood, stain and sealer coats(inciuding UV). The work piece first passes under two large counter rotating spiral hubs, then under eleven rotating discs that oscillate from left to right. This provides very uniform edge breading in whitewood sanding and eliminates most (if not all) hand sanding of the sealer coat. -- The patented combination of roller and rotating discs provieds very uniform sanding across the entire work piece, even into deep profiles without loosing detail. -- SPECIFICATIONS OF MACHINE --Thickness of work piece Min: 10mm (1/2")-- Max: 80mm (3") --Feed belt width Max:1350mm (53") --Feed belt motor 1.5 KW (3Hp) 3-15 M/min (10-50 Ft/min) --Top sanding roller 2.2KW (3Hp) 25-300 O/min (RPM) --Disc Rotation 2.2KW (3Hp) 25-300 O/min (RPM) --Disc Osciliatiojn ).37KW (0.5) 10-60 O/min (RPM) --Vacuum motor 7.5KW (10Hp) --Machine weight 1,800 kg -- Aproximate Machine dimensions based on similr machine W:2000mm (6'7")/ L:2780mm (9'2")/ H:6'11")

LOEWER DISC MASTER 3DBB Denibbing Sander with (2) Sanding Stations, 53" Width Capacity:53" Width cap. Denibbing Sander with a patented combination of rollers and rotating/oscillating discs make the LOEWER Discmaster 3DBB Sanding Machine the ideal finishing solution for entry doors, cabinet doors, drawer fronts, sheet goods, shutters, face frames, furniture and much more. -- Ideal solution for all sanding applications including whitewood, stain and sealer coats (including UV). -- Operation: The workpiece first passes under (16) rotating discs with abrasive brush loadings and then under (2) large counter-rotating spiral brush roller type hubs,Head Configuration: -- 1st Unit: (16) Rotating discs 250 mm (10") diameter each with (24) keyways 75 mm (3") long that oscillate from left to right; provides very uniform edge breading in whitewood sanding and eliminates most (if not all) hand sanding of the sealer coat. The discs are variable speed from 50 - 300 RPM by frequency inverter. Eccentric orbital disc movement (patent pending). Separate height adjustment of the disc station to run discs only or brush rollers only or everything together. Digital display to show the height of the discs. -- 2nd Unit: (2) - 400 mm 16" dia. rotating brushes sanding rollers powered by 2.2 kW gear motor with external coolers. -- Variable spindle speed 14 - 300 RPM adjusted by frequency inverter on each spindle and separately adjustable. The first drum rotates with the feed and the second rotates against the feed. Includes a panel blow-off station. -- The patented combination of rollers and rotating discs provides very uniform sanding across the entire workpiece, even into deep profiles without losing detail. Specifications: -- Disc oscillation by 0.37 kW (0.5 HP) motor, (0 - 60 Cycles/Min). -- Min. part thickness 4 mm (3/16") and max. 4"; -- Vacuum bed with 7.5 kW (10 HP) motor; Vacuum blower outlet on side of the machine has 200 mm outlet. -- Variable vacuum bed conveyor feed speed from 3 - 15 m/Min (8 - 50FPM). -- Pneumatic belt centering system. -- Fixed bed height for installation in a line. -- Separate variable speed adjustment for disc & roller. -- Antistatic brush strip device. -- Control panel Left Side-mounted. -- Emergency stop pull cords at both infeed and outfeed. -- Dust extraction outlets 3 x 80 mm (3.2") 4 x 140 mm (5.6") and 1 x 200 mm (8").Equipped with: -- PLC Touch-screen control: Simple & user-friendly "TOUCH SCREEN" PLC control with color monitor; PLC storage capacity for up to (25) individual sanding programs; -- the PLC control interface also allows for easy machine connection to a flat-line, tow-line or hanging-ling finishing system.

Dust Collection Pipe (Snap Ring type Pipe)Quantity - Diameter - Length Description(2) 22" - 12" - 38" Branch.(1) 24" - 12" - 38" Branch.Many loose Snap Rings in the tote.(1) 25" - 59" Pipe.(4) 22" - 59" Pipe.(2) 24" - 59" Pipe.(1) 24" x 22" x 6" 21"; Reducer with branch.(1) 22" x 20" x 12" 33"; Reducer with branch.(1) 11" x 10" x 10" 29"; Reducer with branch.(1) 12" Auto gate.(18) 10" - 59" Pipe.(2) 9" - 59" Pipe.(1) 11" - 59" Pipe.(4) 12" - 59" Pipe.(1) 22" - 29" Pipe.(1) 20" - 50" Elbow.(1) 20" x 16" x 12" - 33" Reducer with branch.(1) 24" x 24" x 10" - 29" Branch.(1) 24" x 24" x 6" - 24" Branch.(1) 16" x 12" x 7" x 7" - 45" Reducer with branch.(1) 22" x 22" x 6" - 20" Branch.(7) 12" - 59" Pipe.(4) 14" - 59" Pipe.(1) 16" - 43" Pipe adj.(18) 8" - 59" Pipe.(68) 6" - 59" Pipe.(10) 3" - 59" Pipe.(2) 8" - 32" Pipe.(32) 8", 9", 10", 11" - 59" Pipe.(46) 5" - 59" Pipe.(8) 7" - 59" Pipe.(39) 4" - 59" Pipe.(1) 14" x 12" x 6" - 21" Reducer & branch.(1) 14" x 14" x 6" - 21" Branch.(20) 3", 4", 5", 6" - Various pipe. (1) 6" x 6" x 6" - 21" Branch.(1) 10" x 10" x 4" - 17" Reducer.(1) 10" x 7" x 7" - 23" Reducer.(1) 10" x 9" x 4" - 17" Reducer & branch.(1) 10" x 7" x 7" - 23" Reducer & branch.(1) 10" x 7" 9" Reducer(5) 10" - 18" 90° Elbows.(20) 5" - 8" 90° Elbows.(7) 7" - 8" 90° Elbows.(23) 6" - 8" 90° Elbows.(20) 8" - 20" 90° Elbows(4) 5" - 6" Saddle.(1) 7" x 4" x 4" - 19" Reducer & branch.(2) 8" x 7" x 6" - 21" Reducer & branch.(1) 7" x 6" x 4" - 17" Reducer & branch.(1) 11" x 11" x 9" - 31" Branch.(1) 12" x 8" x 8" - 19" Reducer & branch.(1) 7" x 6" x 5" - 19" Reducer & branch.(1) 11" x 10" x 4" - 17" Reducer & branch.(1) 14" - 39" - 90° Elbows.(1) 9" - 20" 90° Elbows.(2) 10" - 16" 90° Elbows.(1) 7" 22" Pipe.(1) 10" x 10" x 4" - 17" Branch.(2) 10" x 8" x 6" - 21" Reducer & branch.(1) 14" - 39" 90° Elbow.(1) 9" - 20" 90° Elbow.(2) 10" - 16" 90° Elbows.(1) 7" - 22" Pipe.(1) 10" x 10" x 4" - 17" Branch.(2) 10" x 8" x 6" - 21" Reducer & branch.(1) 8" x 8" x 6" - 23" Branch.(1) 12" x 10" x 6' - 21" Reducer & branch.(1) 8" x 6" x 4" - 18" Reducer & branch.(28) 4", 5", 6", 7", 8", 9", 10", 14" Misc.(1) 14" x 11" x 6", 6" 42" Reducer & branches.(1) 8" x 7" x 6" - 21" Reducer & branch.(1) 12" x 7" x 7" - 34" Reducer & branch.(1) 12" x 11" x 4" - 17" Reducer & branch.(1) 5" x 5" x 5" - 17" Branch.(1) Batch 50' - 24" Straight pipe.(1) Batch various 24" - 90° elbow.(1) Batch various 24" - 45° elbow.(1) Batch 150' - 12" Straight pipe.(1) Batch various 12" various fitting.

Call for Price

MAC 120-MCF-572 High Capacity Baghouse Dust Collection system with Rotary Air Lock (RAL) and Medium-pressure Controlled air cleaning dust Filter (MCF). -- Baghouse Capacity: 50,000 CFM @ 7.2:1 Air-to-cloth ratio (ACR), approx. 6,921 sq-ft of filter area based on (572) Filter bags; 120" long x 5" dia. -- Equipped with: (1) AIR TECH size 402, BISW, Backward Inclined Air Handling Fan, Class IV, with 40" inlet, ground-mounted on unitary base, flanged inlet box & outlet. For prior application fan operating point (RPM/SP) is set up for about 41,526 CFM @ 12" WG at 1566 RPM, drawing 119 BHP. the fan is equipped with a variable volume damper on discharge. Fan range is about 40,000 - 55,000 CFM. Powered by a TOSHIBA 150 HP TEFC, 444T, 1800 RPM motor packaged with a belt drive -- Bag Cleaning: Mac "Never-Miss" Cleaning System with rotating arm, diaphragm valve for pulse cleaning Approx. 3 HP positive displacement (PD) pump for bag cleaning at only 7- 9 PSIG. 1 HP direct drive gear motor for distribution arm, integral manifold/surge tank, pneumatically controlled firing mechanism activating the diaphragm valves/nozzles. When cleaning arm & bag segments are correctly aligned air nozzles fire directly into bags without wasted cleaning air. -- Includes: MAC FS24x24 AIRLOCK Rotary Air Lock (RAL) with approx. 2 HP SYNCROGEAR MODULE gear motor; sprinkler package; 60° Cone-shaped hopper attached to MAC at bottom of cone. -- Features: Floor-standing Electrical controls (excluding shared controls) with MOTORTRONICS Solid State AC Softstart for main 150 HP motor. -- Additional Features: Explosion vents. Summer/Winter diverter and return air ductwork. Support structure. Caged access ladder from ground Service Platform and to the top plenum. -- Baghouse constructed of 7 gauge carbon steel containment; one piece body all welded construction, 180" (15') diameter shell panelized unit, walk-in plenum for maintenance and bag replacement. -- MAC design features: MCF 4HVP Pump package. MCF Medium-pressure air requires less HP and yet offers high dust and air collecting efficiency with unmatched baghouse cleaning at lower operating cost. MCF pulses each bag the same number of times with the same amount of air. (Unlike some competitors which clean the inside rows of bags more often than necessary thus wasting energy, causes uneven pressure drop, and bag wear). -- (2) of these identical units are installed per photos, one only is available based on Owner/buyer agreement and price point. Material handling fan/drive is not included and is assumed to stay with the remaining filter unit. -- Overall dimensions: 580.5" high x178.5" square frame with an estimated weight of filter unit (less structure and accessories) 31,000 Lbs. -- Professional dismantling/rigging, truck loading and transportation are available at extra cost. -- NOTE: Per photo #1 on the Ex-Factory website the unit for sale is on the right-hand side. The left-hand unit is not easily accessible.

Call for Price

MAC/SCHENCK 144-RPT-252 STYLE III Baghouse Filter System with Pulse Jet Cleaning and Rotary Air Lock (RAL) discharge.RPT Filters (Rectangular Pulse Top-Removal) Rectangular top removal bodied filter unit designed to handle high air volumes. • Bags are removed vertically from the top clean section. Walk-in plenum so the filter media replacement and maintenance can occur in an enclosure for inclimate weather. -- Baghouse Capacity: 4,770 sq. ft. of cloth consisting of (252) bags, 144" long 16 Oz P84 Top Load bags and bright wire cages. Depending on your application, for example at an air-to-cloth ratio of 3.14:1 it can develop 15,000 CFM. -- Equipped with: (1) PHELPS FAN, Material Handling, WRM-380 CCW-TAU HD ARR. 8 with A-36 inlet flange Performance at 15,000 ACFM & 15" SPWG, 1780 RPM, 315°F, 0.050 #/cu. ft..500' elev. Direct drive MOTOR IS NOT INCLUDED but was designed for 75 HP, 1800 RPM,, 365T. Fan was connected in a negative pressure configuration, flanged inlet & outlet. -- Bag Cleaning; Requires 33 SCFM of clean, dry air at 90-100 PSIG. -- Complete with: Auger on bottom of hopper feeding Rotary Air Lock (RAL) with approx. 1.5 HP gearmotor at 22 RPM.; (3) Rupture style explosion vents.. -- Features: Equipped for High Temperature (400°F) bags Special equipment includes VITON Diaphragm valves, copper line (in lieu of polyflo tubing)high temperature air header connections and hi-temp purge pipe compression on couplings. (2) 2" NPT couplings with plugs are included in the plenum section for future addition of sprinkler/deluge system. -- Filter unit constructed of carbon steel containment with 3/8" x 4" reinforcing ribs. 34" diam. high entry inlet and top outlet. -- Includes: Nema 4 Timer Board and solenoid valve enclosure. Each require 110/60 Hz power supply. Filter has (2) solenoid valve enclosures. -- Dimensions: 492" overall height (ground to top), 156" square sides. Separates into (3) sections: Top Plenum, filter section and bottom hopper/support steel. -- Dismantling/rigging is included. Please inquire for transport to your location.. -- NOTE: Extra high Stainless Steel stack is available if you want it.

Call for Price

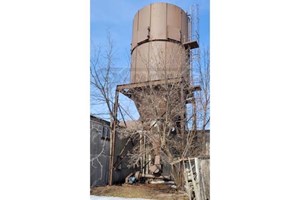

MACDONALD STEEL 65 ST Dust Collector System with Shaker filter cleaning, Rotary Air Lock, and 18' dia. housing. -- Specifications: Capacity for 65,000 CFM, 18' dia. shell, with 8,199 sq-ft. of filter area for an air-to-cloth ratio of 7.7:1. T-150 polyester bags 14 oz. with a 30 - 40 CFM.@ 1/2" WG permeability. -- Current Fan configuration: System 1: Fan inlet of 33" at 32,500 CFM; System 2: .Future capacity for a second fan as per System 1. Return air duct is 42" x 72". -- Filter Cleaning: Top mounted electrically operated & timed mechanical shaker, approx. 2 HP motor which will automatically operate on all shutdowns. -- Equipped with: MACDONALD 18" Rotary Air Lock (RAL) with bottom eductor/T-section for connection to a relay/transfer fan (not included.). -- Complete with Fire Damper, Summer/Winter Damper with Silencer, Explosion doors, safety ladders, and access platform. -- Features: 13" MH/HT 20 HP Transfer/Transport fan -- Overall height is currently 57'-3" with 12' clearance under RAL. Weight of filter with structural steel is 29,000 Lbs plus fan is about 3,000 Lbs. -- Shell panelized construction (made of separable panels allowing for road/Hwy travel).Professional rigging, loading and transportation are available at extra cost; quote upon request.

Call for Price

MACDONALD STEEL 37 PTFU Dust Collector with Shaker type bag cleaning. -- 30,500 CFM, 150 HP blower with 37" inlet dia., 4,354 square feet of cloth filter area with 7.0 to 1 air to cloth ratio, (114) 9" dia. X 168" (14') long bags, 1.5 HP shaker motor, -- MACDONALD 37 AT main fan belt driven by a 150 HP WEG motor. Silencer on fan discharge. 11' dia. baghouse with 2,160 cubic feet storage cap; overall height of approx. 55' -- Includes: Retrofitted hopper with transition to bottom auger to Rotary Air Lock (RAL). Explosion Doors -- Features: Enclosure with SIEMENS Variable Frequency Drive (VFD) for efficient ramp-up control convenient fan speed control as needed.Summer/Winter diverter on return air line. Truck level loading .'Y' branch on inlet with approx. 33" & 16" supply lines. -- Complete with: Electrical control panels with with starters for auger and RAL. All external ducting, and about 100' manifold of 33" dia. steel flanged main trunk supply line. Safety ladders & access platforms.

Call for Price

MACDONAL STEEL - 26 PT: Dust Collector with RAL/Auger and Diverter Gate.Overall data: 16,700 CFM; 1,780 sq/ft. of cloth area comprised of: (85) Bags: 8" Dia. & 120" long; 60 HP blower; 26" inlet dia. with retrofitted Auger/Rotary Air Lock. -- Equipped with: Electrically operated mechanical bag shaker; back pressure damper on inlet manifold; Diverter/Abort Gate. -- Complete with: Safety hoop access ladder; (1) access platform to filter media; (1) top mounted fan/motor; silencer on return air. -- Starter/electrical control panels and disconnects inside/outside for each drive. -- Used 150 HP; rated VFD is available at extra cost.

Call for Price

MACHINEX - SRM-1: SamurAI Sorting RobotThe SamurAI is a 4 articulation Robot, which: Targets designated products to capture, maneuver, and deposit into the respective chutes.Includes: Unique integrated Suction System driven by a blower, enabling the removal of small and light particles (such as plastic film) into a dedicated Cyclone and lowering compressed air requirements .Specifications: -- Up to (70) picks per minute (nearly double the average pick rate (30 - 40) picks/minute) of a human sorter. -- Up to 95% efficiency of targeted product recognitionEquipped with: -- (1) Sorting Camera. -- (2) Sorting Arms. -- HMI Interface and controls. -- Currently over a 32" W Conveyor. -- Adaptive Concept: Designed for multiple robot configurations and extended conveyor width options. -- Material handling flexibility: Recovered products handled through fixed sorting chutes or portable bins -- Lighting encapsulation: For optimal product recognition in all possible sorting environments. -- Ergonomically designed: Maximize productivity by easy access for preventative maintenance. -- Temporary manual sorter replacement. -- Safe working environment with easy access inside the machine for a sorter to replace the robot during planned maintenance shutdowns.Positively: Extracts recyclable commodities from a specific stream of material (e.g.: plastics, fiber or metals from a reject line); Negatively: Sort a dedicated stream from all its contamination (e.g.: PET quality control after an optical unit).Prepping machine and loading on your truck is included.

$79,500

MACMAZZA TS 90 FRONT LOAD, AUTO. PANEL SAW: -- Specifications: -- 169" Cutting length; 2.83 effective cutting height, 12 HP main saw motor. -- Features: -- Variable saw carriage travel speed 3 - 328 FPM, constant return of 328 FPM; electronically controlled overhead program fence, rack & pinion driven on both sides, forward & return speed 2 - 164 FPM, equipped with (6) clamps. -- PC-Based LENOVO 90GA computer control with CELERON Quad-Core J3455 Processor & 19" color monitor, 4 GB RAM, 1,000 GB Hard drive, (6) USB Ports. -- Complete with: -- Rear table constructed of aluminum profiles with plastic rollers, (3) front air floatation tables; side pressure device for crosscutting on pressure beam.Photos not of actual machine.

MAGGI SYSTEM 23 Construction Hole Boring Machine Adjustable 23-spindle boring head on 32 mm centersSpecifications: -- Stops in 0° & 90° with pneumatic positioning in vertical & horizontal. -- 0" - 2-1/2" Adjustable drilling depth with patented setting device. -- (2) Patented material clamps with auto-setting & safety feature. -- Head height fine adjustment with a mechanical digital readout. -- 2 HP - 2,800 RPM Motor. -- 38" x 16" Table with mechanical digital side fences for mirror-image. -- 120" Line Boring fence with (4) repeat stops & spring loaded repeat pin. -- Foot actuated pneumatic clamps & drill cycle. -- Magnetic starter, overload protection and (1) set of "quick change" chucks. -- Dust Outlet: 3".Net weight: 630 Lbs; Dimensions: 51.7" x 37.8" x 50" Tall; Crated Dimensions: 44" x 38" x 42" Tall; Crated Weight: 664 lbs.Available in single phase ... Add $ 600.00

MAGGI SYSTEM 29 CONSTRUCTION/LINE BORERAdjustable 29-spindle boring head on 32 mm centers with position indicator. -- Stops in 0° & 90° with pneumatic positioning in vertical & horizontal. -- 0" - 2-1/2" Adjustable drilling depth with patented setting device. -- (2) Patented material clamps with auto-setting & safety feature. -- Head height fine adjustment with mechanical digital readout. -- 2 HP - 2,800 RPM Motor. -- 45" x 16" Table with mechanical digital side fences for mirror-image. -- 120" Line boring fence with (4) repeat stops & spring loaded repeat pin. -- Foot actuated pneumatic clamps & drill cycle. -- Magnetic starter, overload protection and (1) set of "quick change" chucks. -- Other Accessories also Available!

MAGGI SYSTEM 46 Double Head Line Boring Machine:Heavy Double Head Line Borer with (2) 23-spindle heads; 32 mm spindle spacing.Specifications: -- Drilling from the bottom up and with 5-1/8" - 25-19/32" distance between rows. -- Drilling vertically from the bottom allows the chips to drop down falling out of the holes. -- Drilling depth of up to 2-1/16" (55 mm) max., takes only seconds to set. -- (2) 2 HP - 3,500 RPM Commercial Duty motors; spindles with steel gears & high quality bearings. -- Easy repetition by (2) air index pins for continuous line drilling, left and right roller track supports extend up to 400 mm (15-3/4") for larger panels.Features and Includes: -- 120" Back fence with (4) repeat "flip" stops; includes 27-3/4" (704 mm) fence for quick positioning of flip stops. -- (6) Pneumatic holddowns to automatically actuate when the drill cycle begins. -- (46) "Quick Change" chucks for easy tool change. -- Magnetic motor controls and 1/4" air regulator with filter and oiler; 100 PSI required air pressure.

MAGGI SYSTEM 35 CONSTRUCTION/LINE BORINGAdjustable 35-spindle boring head on 32 mm centers with position indicator. -- Stops in 0° & 90° with pneumatic positioning in vertical & horizontal. -- 0" - 2-1/2" Adjustable drilling depth with patented setting device. -- (2) Patented material clamps with auto-setting & safety feature. -- Head height fine adjustment with mechanical digital readout. -- 2 HP - 2,800 RPM Motor. -- 45" x 16" Table with mechanical digital side fences for mirror-image. -- 120" Line boring fence with (4) repeat stops & spring loaded repeat pin. -- Foot actuated pneumatic clamps & drill cycle. -- Magnetic starter, overload protection and (1) set of "quick change" chucks. -- Other Accessories also Available!

Northtech NT SLR-16SC Precision 16″ Straight Line Rip Saw FEED SYSTEM --Saw motor: 15HP, 3PH 230/460V -- Feed: 1.5HP variable from 40′ – 120′ FPMPRODUCT DIMENSIONS -- Min. thickness: 3/16″ -- Max depth of cut: 4-1/16″ with 16"; Blade -- Max depth of cut: 3-1/16"; with 14"; BladeSpecifications: -- Direct Drive = Direct Drive -- Feed Hp. = 1.5 Hp. -- Feed System = 4"; Split Chain with True Trac -- Feed Speed = 40-120 FPM -- Assisted Start = Wye Delt"; -- Throat Capacity = 18-1/4"; -- Min. Length = 12"; 2nd Roller to Kickback -- Min. Thickness = 3/16″ -- Max. Thickness = 4-1/16"; W/ 16"; BladeGlue Line Rip = Guaranteed 12′ 4/4 stock @ 50 FPMEquipped with & Features -- Blade Size = 14"; Tungsten Carbide Tipped -- Dust Collection = 1417 Total CFM -- Dust Port Out = 4"; Top 6"; Bottom -- Arbor Diameter = 2″ Arbor -- Idle Rollers = (8) Idle Rollers -- Hold Down Style = 8 Spring Loaded Hold Downs -- Kickback Finger = (59) Lower (32) Top -- Automatic Mechanical Oiler -- Low Oil Warning = Low Oil Shut-off -- Laser = 100mw Laser Light & Mount Bracket

NORTHTECH - NT-KL-920-PRR- B & NT-KL-920 PRR-U, ...Top & Bottom 3-Head Planer Sander3-Head bottom with: Planer, drum and platen; 3-head top with: Planer, drum, and platen 920 mm (36") wide.Capacity: 36" x 5" thickness.SpecificationsBottom Machine Model: "NT-KL-920 PPR". -- Infeed driven Conveyor: 37" x 72" Long. -- 1st Head: Spiral cutterhead; (8) rows of 15 x 15 x 2.5 mm inserts carbide knives; (4) sides for rotation; low tool cost.Cutterhead: 175 mm (7") Dia. and 50 HP motor. Segmented chip breaker before the cutterhead. -- 2nd Head: Contact roller; (280 mm) 11" in dia.; 70 durometers, powered by a 40 HP motor; running at 3,600 FPM belt speed.Sanding belt size: 85" x 37". -- 3rd Head: 3-1/4" Pneumatic Polishing Platen; engineered as a combination station, air-cushioned & adjustable in pressure to various grits and materials application. Powered by a 30 HP motor. -- Lifting & lowering conveyor bed; 1-1/2 HP motor (includes auto. thickness setup device). -- Variable speed: 7.5 HP; inverter duty motor integrated with an AC inverter (VFD); control providing variable feed rate from 15 - 70 FPM for heavy calibration; LED readout feed speed indicator. -- Microprocessor Control for: Conveyor bed positioning to high precision via keypad entry. -- Automatic electronic preset panel thickness gauge/micrometer. -- Automatic Air Jet blast cleaning system on both sanding heads.Top Machine Model: NT-KL-920 PRR-U -- 1st Head - Spiral Cutterhead: (8) Rows of 15 x 15 x 2.5 mm inserts carbide knives; (4) sides for rotation; low tool cost.Cutterhead: 7" (175 mm) Dia.; 50 HP motor.Segmented Chip Breaker: Before the cutterhead. -- 2nd Head - Contact Roller: 11" (280 mm) Dia.; 70 durometers; powered by 40 HP motor; running at 3,600 FPM belt speed.Sanding belt size: 85" x 37". -- 3rd Head - 3-1/4" Pneumatic Polishing Platen: Engineered as combination station; air-cushioned & adjustable in pressure to various grits and materials application; powered by 30 HP motor. -- Lifting & lowering Conveyor Bed: Motor 1.5 HP (includes auto. thickness setup device). -- Variable speed 7.5 HP inverter duty motor; integrated with AC inverter (VFD) control; variable feed rate: 15 to 70 FPM for heavy calibration; LED readout feed speed indicator. -- Microprocessor Control: For conveyor bed positioning to high precision via keypad entry. -- Automatic electronic preset panel thickness gauge/micrometer. -- Automatic Air Jet blast cleaning system on both sanding heads. -- Powered dropdown Conveyor between Bottom & Top machine.Features (includes both machines) -- Massive monoblock base: 3/4" Thick plate steel weldments. -- Large dia. roller hold-downs; ball bearing supported; 65 duro UV rubber are standard features. -- Automatic soft start of main motors (Y-Delta). -- Disc braking/emergency shut down protection for: Sanding belt breaking, non-tensioned sanding belt; and mistracking of sand belt. -- All motors & electrics are CE-approved. -- Electronic oscillating belt tracking system. -- Au

$34,500

NORTHTECH NT-610EL Top & Bottom Planer:24" Wide x 7.5" thick capacity; 1/4" minimum thickness; 12" minimum stock length.Specifications: -- Cutterheads: 25 HP top head; 20 HP bottom head; 5,800 RPM on cutterheads; (6) row spiral insert cutterheads, Carbide knives 15 mm x 15 mm x 2.5 mm 4-sided -- Feed works: 3 HP variable speed feed with speeds from 20 to 75 FPM; 1 HP motorized raise and lower of bed; DP-525 digital thickness controller; Overhead carpet style feed system Equipped with & Features -- Sectional chip breaker; Hard chrome plated bed; Automatic lubrication for feed system; Amp load meter -- Dust Requirements: 3,800 CFM; (1)10" and (1) 7" dust outlet Seller states this machine has less than 600 Hours of use.

NORTHTECH NT-KL-43-RC Wide Belt Sander (2) Heads;43" width cap. Drum, Combination Head.Head Configuration:1st Head: Rubber-covered contact drum with 25 HP motor2nd Head: Combination head with a rubber-covered contact drum and 2-1/4" wide finishing platen, 20 HP motor.Specifications: -- Thickness opening with PLC control, (DP-525 controller) keypad entry automatically adjusts to any thickness with LED readout. -- 37" x 75" Abrasive belts, TRU-TRAK solid state abrasive belt tracking. -- Variable feed drive 13 - 49 FPM, 2 HP motor. -- Endless belt conveyor, infeed and outfeed rubber covered pinch rolls. -- Complete with: 0" - 6" Automatic part thickness set up.Equipped with & Features: -- Infeed and outfeed rubber covered spring loaded holddown rolls. -- Feed emergency stops at infeed. -- Disc brakes on sanding heads, electrical interlocks on main access doors, and motor load meters. -- Note: Year of manufacturing has to be verified.

NORTHTECH - SRS-12 ...Straight Line RipsawSpecifications: --15 HP Motor, 1" dia. saw arbor, speed of 4,500 RPM, 8". -- Max. blade cap.: 12". -- Max. depth of cut: 3-5/16". -- Part length: 8" Min. -- Distance between saw & column: 18"; 60" W x 33" table. -- Feed & Chain: 2 HP Feed drive motor; variable feed speeds of: 59 - 72 - 91 - 111 & 137 FPM. --7" Wide double chain, with automatic chain lubrication.Equipped with & Feature: -- Top pressure system with (6) spring loaded holddown rollers. -- Double row antikickback fingers. -- Adjustable infeed fence. -- Safety side guard. -- 4" Dia. dust hood outlet. -- Push button controls. -- Magnetic starters. - Overhead post for laser mounting.

$197,600

Unassembled Front Load Kiln with Standard Heat and Exhaust -- Interior dimensions: H 17' 6" (5.33 m), D 25' 8" (7.8 m), W 26' (7.9 m). -- Loading Door Opening: height 14'6" (4.4 m), width 25'3" (7.7 m). 1/8" Aluminum Bumper Walls, Top Hinge Door, Exterior Installation. -- Average 4/4 capacity: 25,459 Bd Ft. with 3/4" stickers. Average 8/4 capacity: 33,293 Bd Ft with 3/4" stickers. -- Price shown is for kiln only. -- Standard HP Heat requirement: 382k BTU suitable for drying dark hard woods; Optional high HP Heat requirement: 674k BTU suitable for drying softwood and white hardwoods. -- Electrical requirements: 480 VAC, 3 Ph., 60 Cy; 16.5 kW/Hr. Timber Management Control System with touch screen operator interface, data recording, remote access & networking capability. -- Features: Control room with heated air intake; 12'H x 4'D x 26'W. Top Hinge door opening System includes "230" electric chain hoist. Boiler Room: 12' W x 25' D x 17'6" H. 10' roll up & (1) access door. - Timber Dry Management Network Capability.