704-841-2001

Backed with a massive machinery database considered to be “the blue book” of woodworking machinery), EX-FACTORY Auctions provides a complete assessment of your equipment and allows you to interact with the market real-time in our dynamic Online Auction!

2103 Results Found

704-841-2001

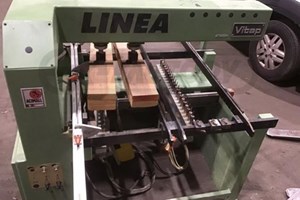

VITAP LINEA 42 Line Boring SystemSpecifications: -- (2) Drill heads of (21) spindles ea., drills from bottom up, ea. support with 2 HP motor and (21) spindle boring block w/panel support mounted on top; -- Drills panels from 100 - 3,000 mm in length, and 100 - 950 mm in width. Complete with: -- Digital readouts for boring blocks, 2,000 mm bar scale fence with (5) adjustable flip stops. -- (2) Moveable overhead pneumatic holddown cylinders, foot pedal for clamping & boring cycle.

$46,900

VALPATO LBK-150-ST 1 Feed Through Profile SanderTECHNICAL FEATURES: An added small needle type drum sander can be fitted with drum sanding aggregates of 25, ­30, ­35,­40, ­45 ­50 mm diameters which can be used for tighter curves and smaller radius sanding requirements. Storage compartments (2 in total) are located on each machine extremities, these are easily accessible and can be used for sanding belts and various tooling storage. Sanding belt motor power: 3 Kw Abrasive head motor power: 1.5 Kw Oscillation motor power: 0.38 Kw Feed motor power: 0.75 Kw Motor power for electrical adjustment of sanding group: 0.19 Kw Machine voltage: 480/3/60 Full Load Amps @ 480V: 15A Compressed air: Not required Dust collection requirement one (1) only 6" (150mm) port: 950 CFM Sanding belt speed: 14 Mt/sec Variable speed of the belt: from 5 to 25 m/min Sanding belt dimensions: 150 x 2640 mm Height of working table: 930 mm Dimensions of front working table: 1980 x 250 mm Machine dimensions: 2500 x 900 x 1600 mm Net weight: 1000 KMAIN FEATURES: User friendly PLC touch screen control panel is accessible from 360° by the operator, the control panel is centrally located on the infeed end of the machine. Factory installed variable feed drive (VFD), enables machine to run from 5 M/Min to 25M/min (+/­ 80 ft/Min). The entire sanding plenum rise and fall is motorized, it can be adjusted vertically in height to utilise the full height/width of the sanding belt. An oiling unit ensure long life of sanding plenum rise and fall master cylinder.

Call for Price

Static tipping load at full turn 22,265 lbsBucket capacity 2.9 - 9.2 yd³Log grapples 1.6 - 2.9 yd²Operating weight 31,968 - 38,140 lbsBreakout force 31,470 lbfEngine Volvo D6JMax power at 1,400 - 1,900 rpm...ISO 14396 gross 184 hp...ISO 9249, SAE J1349 net 184 hpMax torque at 1,400 rpm...ISO 14396 gross 689 lbf ft...ISO 9249, SAE J1349 net 689 lbf ftTires 20.5R25 600/65R25

$49,500

VOORWOOD M 15A CNC Round End Tenoner & Mortiser for 45° Door --The "M15A" Miter Machine is designed to rapidly make mortise and tenon cuts at 0°, 45° Only, . Parts can be up to 1.5"; thick and up to 4"; wide, and of ANY length. --A primary application for this machine is for miter cabinet door frames. Parts can be quickly transferred from left to right. They are mortised on the left side of the machine and tenoned on the right. The machine can also mill the slots. --Specifications & Equipped with: -- The mortise station has (3) servo-controlled axes (X, Y, and Z) that are coordinated by the machine controller to achieve complex CNC motion. It is equipped with a collet-style router spindle for cutting. The tenon station uses the same X- and Y-servo-controlled axes as the mortise station and is configured for pneumatically actuated in-and-out movement along the Z-axis. The tenon station is equipped with a direct drive shaper spindle for cutting. -- -- Pneumatic clamping assemblies with non-marring urethane pads are mounted to the hold-down assembly to secure the parts during cutting and these can be adjusted to various locations over the cutting surface. -- -- M15 Miter Machine operator interface consists of a colored touch screen. For simplicity, the entire calibration, setup, and monitoring of the machine are accomplished using only four touchscreen displays. The program designs the depth and location of both the mortise and the tenon. When the design is complete, it is saved in a recipe format. Once this recipe is opened, the operation is as simple and boils down to feeding the substrate into the machine. -- -- The full-color touchscreen panel is located on the front of the machine to provide easy access for setting up or operating the machine. Clamping and shaping operations are controlled by operating lighted pushbutton switches.

$16,750

VOORWOOD "A 515 GH" Arch Door Sander with Floating Head ARCH SANDER with: (4) 1.5 HP Motors for precision sanding; quality sanding using Disc sanding at continuous feed. Equipped with: -- (4) Floating Sanding Stations equipped with: 1.5 HP Precision balanced drive motors and quick change spindles. -- Infeed & outfeed (1st and last) spindles equipped with: Double collets and angular, horizontal & vertical adjustments with accurate and repeatable digital readouts. -- PLC Control with: Monitor at eye level height.Feedthrough Arch Machine capable of sanding arch profiles on cabinet door components, plus can do straight cuts.. .

WADKIN "VISAGE PLUS" Profile Grinder Specification -- 12-1/8" Max. arbor capacity; -- Max. cutting circle is 13.8", min. cutting circle is 2-3/4". -- Max. depth of profile is 1.57", --Grinding wheel dia. is 9"; infinitely variable head tilt mechanism 0° - 15° maximum.Equipped with & Features -- 2 HP Grinding motor, -- Spindle speed up to 3,600 RPM; -- Max. coolant tank cap. is (8) gallons; min. is (4) gallons

$17,900

WADKIN "GA-220" 5-Head Feed Through MoulderSpecifications: -- 5-Head, with 8-5/8" x 4-5/8" cutting capacity (220 mm x 120 mm) -- 40 mm Spindle diameter with cutterhead speed of 6,000 RPM. -- Head sequence: Bottom 10 HP, Right 7-1/2 HP, Left 7-1/2 HP, Top 15 HP, Bottom 10 HP motor. -- 2 HP variable feed speed 19 to 72 FPM, chain drive. -- Currently wired for 460 Volt, 3-Phase power.

Call for Price

WADKIN GD 220 6-Head Feed Through MoulderSpecifications: -- Working capacity: 230 mm W x 130mm H (9.06" W x 5.12" H) Timber admitted, 220 mm W x 120 mm H (8.66" W x 4.72" H) Finished timber. -- Head Sequence: Bottom 7-1/2 HP, Right 7-1/2 HP, Left 7-1/2 HP, Top 15 HP, Bottom 10 HP, & Universal 7-1/2 HP. -- Spindle dia. 40 mm (1.57"), Spindle speed 6,000 RPM. -- Variable feed speeds 6 - 22 MPM (20 - 72 FPM).Equipped with: -- Right, Left & Top heads with Mechanical digital readouts. -- 1/2 HP Motorized feed beam, 2.2 kW Feed motor, 3 HP Cardan drive, Reverse feed, 5-1/2" Dia. Hardened & Chromed steel feed rollers up to top head, 2" x 2" Polyurethane feed rollers after top head, All feed & pressure rollers move with rise & fall of feed beam. -- 2 M (78.74") L Infeed straightening table. -- Manual bed lubrication. -- Sound enclosure.

$4,950

WADKIN CP 32 Sliding Table SawSpecifications: -- 10' Cutting length sliding table saw with scoring unit. -- Equipped with: -- 9 HP 2-speeed (2,880 & 4,080 RPM) Main motor and 3/4 HP, 9,900 RPM scoring motor; 14" (standard) - 16" max. dia. saw blade. -- 4" Dia. scoring blade; 0° to 45° tilting arbor; sliding table size 15-3/4" x 125". -- Fixed table 29" x 42"; 36" max rip cap. from saw blade to rip fence.

Call for Price

This item is in an Auction on exfactoryauctions.com. Go here to view item: http://exf.ac/i6h WADKIN JET-3 Single End Tenoner/End Jointer Specifications: For Windows, doors, finger jointing, & stair strings. Stock type: PAR & Moulded. Max. tenon length 120 mm (4.72"). Max. stock width 150 mm (5.91"), Max. stock length: Unlimited, Max. stock thickness: 150 mm (5.91") for Rear tables, 280 mm (11.02") for Front table, & 450 mm (17.72") for Multiple tables. Vertical table adjustment 230 mm (9.06"), Horizontal table adjustment 25 mm (0.98"). Cutterhead dia. 250 - 322 mm (9.84" - 12.68"). Cutterhead speed 3,600 RPM. Max. cutting speed 4 MPM (13 FPM), Return speed 8 MPM (26 FPM). Equipped with: (3) 7” x 27-1/2” Multi-level tables, Each with Adjustable height, Fence, & (2) with 3” Dia. Pneumatic hold-downs, Allowing machining of (3) separate pairs of parts in (1) pass or All joints of window frame/sash in (2) passes. (1) Trim/hog saw & (1) 50 mm (1.97") Dia. x 240 mm (9.45") L Stackable spindle with 7.5 kW (10 HP) - 3,420 RPM Motor, with Automatic brake.

Call for Price

WADKIN "GD 220" 5-Head Molder8-5/8" X 4-3/4" cap. - Head sequence: Bottom 7.5 HP, right 7.5 HP, left 7.5 HP, top 10 HP, bottom 7.5 HP motor.Other Specifications: -- All spindles 40 mm dia. at 6,000 RPM, with vertical and horizontal adjustments; electric spindle braking; (2) digital position indicators with tool radius compensation fitted to the horizontal movement of the right side head and vertical movement of the top head. 0.5 HP Motorized feed beam with pneumatic feed hold-down wheels; -- Cardan drive variable feed speed 18 - 72 FPM, 3 HP feed drive, reverse feed, 5-1/2" dia. hardened and chromed steel feed rollers up to top head, polyurethane feed rollers 2" x 2" after top head; all feed and pressure rollers move with the rise and fall of the feed beam. -- Diameter of cutting circle: minimum 100 mm all heads; for planing, maximum 125 mm all heads; and, maximum of 195 mm all heads for moulding. -- Complete with: Manual bed lubrication, 2-meter (78") infeed straightening table, sound enclosure and owner's manual.Like New Condition - this Moulder has never been used, and is still sitting on factory shipping pallet.

Call for Price

//This machine is in an Auction on exfactoryauctions.com// //Link to machine: http://exf.ac/i6c WALKER 14" Bench-Top Vertical Band Saw Specifications: Table size 17” LR x 18" FB x 20” H. Maximum height under guard 8". Equipped with: 3/4 HP - 1,725 Motor. 16” Rubber-covered spoked wheel.

WEB MECAHNICAL JET 10M Jet Air Oven Supply Side complete with the following: -- 400,000 BTUH rating, 3,200 CFM forward curved blower, 5 HP motor 575 V /3 Ph /60 Cy. -- Inlet filter section HEPA 99% DOP rated, Magnehelic gauge across the filter section. -- Thermometer to show outlet temperature, Thermostat to set and control temperature design from 60° -70° C, -- Jets designed to control flow across the belts. Exhaust Side complete with the following: -- Vane axial fan set to exhaust 600 CFM,1/2 HP motor. -- Direct drive fan with motor out of air stream, external grease fittings for lubrication.Heating Module: -- Air makeup sized for 3,200 CFM, 2 HP motor, rated for 400,000 BTUH. --Fan to exhaust through 2"; pleated filter and 12"; HEPA filter, Down discharge,3 HP motor, 3,200 CFM @ 2.0"; E.S.P. -- Engineered for 90° F temperature rise, 0.4 MBTU/hr hydronic coil, features FUJI temperature selector. Conveyor: -- Robust 10-gage steel frame, Novo 40 grey belt designed for up to 90° C and with Auto tracking mechanism. -- Large size 6"; driver and idler pulleys, Support pulleys 3"; as required. -- Heavy duty NORD gear box and a 2 HP direct coupled motor. OPTIONAL (Not included in Price):IR Adder (Lamps): -- Three (3) MW IR lamps in the center of the oven, Three (3) MW IR lamps at the end of the oven, -- Heated length of lamps 54";, dual gold plated element, 3,200 watts per bulb. -- Lamps are designed to sit between the jets on the oven with lamps 8"; (200 mm) above belt and 8"; apart. - Please add ...$ 7,700Control Panel for the above (600 V - Electric) complete with: -- Line interlock, E-stop, fuses, disconnect switch, DC power supply. -- Phase angle controller to control two (2) banks of three (3) lamps. CSA approved panel. - Please add ...$ 12,100BOILER: -- One (1) RBI dominator boiler "DB 600" to supply up to 600,000 BTUH. - Please add ...$ 18,900

Call for Price

WEB MECHANICAL HYDRONIC OVEN - Low Velocity Flash Off - STAGE # 1 and High Velocity Bake Oven - STAGE # 2 STAGE # 1, Low Velocity Flash Off Oven. -- The oven consist of one (1) only hot water oven, 14' wide x 9' high x 30' long with Air flow requirement of 30 FPM/ 9,000 CFM.Supply side complete with the following: -- 400 000 BTUH heat exchanger -- Motor/blower, 2 HP 575 V / 3 Ph / 60 Hz -- Thermometer to show outlet temperature -- Thermostat to set and control temperature to design temperature -- RTD's (1) for accurate oven dispersion temperature -- Eighteen gage galvanized steel panels -- Perforated metal side walls for even air distribution -- Design temperature of 30 -40°C -- Adjustable inlet mixing damper with intake filter (70% recycle) -- Exhaust fan for combustible gasesExhaust will be complete with the following: -- Size 14 direct drive aluminum fan wheelset to exhaust 30% of the contaminated airflow (2,500 CFM) -- Direct drive with the motor out of air stream -- External grease fittings -- Fan module c/w aluminum extrusions and galvanized panels, and will be complete with HEPA style filter, -- DWDI fan, space for hot water heat exchanger STAGE 2 HIGH-VELOCITY OVEN BAKEThe oven consist of one (1) only hot water oven, 14' wide x 9' high x 20' long with Air flow requirement of 50 FPM/ 9,000 CFM Supply side will be complete with the following: -- 1,500,000 BTUH heat exchanger -- 10,000 CFM -- Motor/ blower 5 HP 575v / 3 Ph / 60 Hz -- Thermometer to show outlet temperature -- Thermostat to set and control temperature to design temperature -- Eighteen gage galvanized steel panels c/w 3" insulation -- Perforated metal side walls for even air distribution -- Design temperature of 40 - 60C 104 - 140 F -- Adjustable inlet mixing damper with intake filter (85% recycle) -- Exhaust fan for combustible gases Exhaust will be complete with the following: -- -- -- Size 12 direct drive aluminum fan wheelset to exhaust 15% of the contaminated airflow (1,500) CFM) -- Direct drive with motor out of air stream -- External grease fittings There will be two (2) air knives one at start of the oven and one art the exit to control heat and fume exhaust Air knives will be complete with Multivee filters for inlet air Fan module c/w aluminum extrusions and galvanized panels will be complete with HEPA style filters, DWDI fan, space for hot water heat exchanger.

Call for Price

WEEKE ABD 050 CNC BORE, GLUE & DOWEL INSERTER: -- Specifications:(1) Horizontal drilling aggregate with (1) individual spindle; with servo control of the "X" Axis; (1) glue & dowel injector with glue flow control; (1) vibrating hopper dowel feeder. -- Working Capacity:Part size: Length 20 mm - 1,250 mm (.75" - 49") Width 20 mm - 800 mm (.75" - 31.5") Thickness 10 mm - 60 mm (.4" - 2.4") thick.Machine is set up for 8 mm Dia. x 30 or 35 mm long dowels -- Work Area(2) Separate working fields with (4) pneumatic top clamps can process up to (2) parts independently on the left-hand, right-hand or center stops; work pieces can be loaded in (1) field while being machined in the other to allow fast production of varying parts. -- Operator Interface:PC Front-end with Homag Power Control PC 85T, WoodWOP 5.0 operating system with graphic programming & error messaging.17" TFT flat screen monitor, CD-RW drive, 1.44 MB floppy drive, standard keyboard & mouse; Software allows program design with automatic mirror-image by use of an active center stop located 600 mm (23.6") from zero. -- Complete with:Bar code control reader. All manuals, documentation & program disk provided with machine. -- Actual Model is WEEKE ABD 050.

WEEKE ABD 100 CNC BORE, GLUE & DOWEL INSERTER: -- Specifications:(1) Horizontal drilling aggregate with (1) individual spindle; (1) glue & dowel injector with glue flow control; (1) 23" Dia. x 4" D vibrating hopper dowel feeder. -- Working Capacity: Material size from 20 mm - 1,250 mm (.75" - 49") long, 50 mm - 800 mm (1.9" - 31.5") wide, 10 mm - 60 mm (.4" - 2.4") thick. Machine is set up for 8 mm dia. x 30 or 35 mm long dowels (additional dowel sizes are optional). -- (2) Separate working fields with (4) 2-3/4"; LR x 3"; FB pneumatic top clamps can process up to (4) parts independently on the left-hand, right-hand or center-stops; work can be loaded in (1) field while it is being machined in the other to allow fast production of varying parts. -- Operator Interface:PC Front-end with Windows XP + Weeke "WoodWOP 5.0" operating system with graphic programming & error messaging; USB front side bus, 17" TFT flat screen monitor, CD-RW drive, Modem, standard keyboard & mouse.Software allows program design with automatic mirror-image by use of an active center stop located 600 mm (23.6") from zero. -- WEEKE "ABD 100" is designed for small or large capacity horizontal drilling, gluing and dowel insertion; built on a Heavy Duty welded steel base; main horizontal beams hold the carriage for the boring head and glue/water injector. -- Complete with: HAND-HELD PRODUCTS "ADAPTUS 5.0 3800G04E" Handheld Barcode Reader.

Call for Price

WEEKE VANTECH 480 FLAT TABLE MACHINE (W/ATC/BORING): -- Specifications: 4' x 8' Flat Table Bridge style gantry machine with User-Friendly "S/C Tech" "MATRIX" grooved phenolic vacuum table. -- Working Area: "X" Axis is 98.4" (2,500 mm); "Y" axis 49.2" (1,250 mm); "Z" axis stroke is 9.6" (243.8 mm); max. material thickness of 3.9" (99 mm). -- Positioning Speed: "X" Axis is 236 FPM (72 MPM); "Y" axis is 203 FPM (62 MPM); "Z" axis 82 FPM (25 MPM).The head travels via AC brushless drives & THK linear motion guides on all axes. -- Worktable: User-Friendly "S/C Tech MATRIX" grooved phenolic vacuum table for easy vacuum pod placement.(3) Pneumatic "X"/"Y" locator/positioning pins. -- Boring Unit(6) Independent vertical spindles with: (3) in "X" Axis & (3) in "Y" axis. -- Machining: (1) 12 HP (9 kW) High-speed electro-spindle router with: "HSK F 63" Adaptor; constant duty; variable speed from 1,250 - 24,000 RPM; RH or LH rotation.(1) 7-Position ATC rack located at the LH end of machine. -- Machine & Operator Control: PC Front-End with: WEEKE "PC 85T" + Windows "XP" + WoodWOP Operating System.Free-standing control cabinet with: 17" TFT Color graphic monitor, keyboard for data entry, PC 85T hand control pendant; EtherNET interface for LAN connection to office PC; RS-232 serial interface; USB ports.BECKHOFF Programmable logic control for: (3/4) Axes: Linear, circular & helical interpolation; the controller is contained in a separate free-standing, dust-free control cabinet that can be placed at either the LH or RH side of the machine. -- Complete with: (4) 100 cbm/Hr Vacuum pumps; Tool Length Control; light curtain (the machine will stop when the operator enters the work area); safety fencing. -- Actual Model is WEEKE VANTECH 480.

$70,000

WEEKE VANTECH 512 CON2/BHP 008 FLAT TABLE MACHINE (W/ATC/BORING): + AUTO IN-FEED/RAKE/OUT-FEED: -- Specifications:5' x 12' Flat Table "Bridge Gantry" machine with User-Friendly "S/C Tech" "MATRIX" grooved phenolic vacuum table. -- Working Capacity: "X" Axis 156.7" (3,980 mm), "Y" axis 61" (1,550 mm), "Z" axis stroke is 9.6" (243.8 mm); max. material thickness is 3.9" (99 mm). -- Positioning Speed:"X" & "Y" Axes 315 FPM (96 MPM); "Z" axis is 82 FPM (25 MPM).The head travels via AC brushless drives & THK linear motion guides on all axes. -- WorktableUser-Friendly "S/C Tech MATRIX" grooved phenolic vacuum table for easy vacuum pod placement.(6) Pop-up pneumatic locator/positioning on the front side & (1) on the back side in "X" axis & (2) pop-up pneumatic locator/positioning pins on RHS facing side in "Y" axis.(4) Vacuum Table work zones can be used independently or together for full table area Foot pedal vacuum zone controls. -- Boring Unit1.5 kW (2 HP) Motor, with "Quick Change" drill bit holders; programmable variable speed from 1,500 - 7,500 RPM; -- Machining(1) 12 HP (9 kW) High speed constant duty, variable speed electro-spindle router with "HSK F 63" adaptor.Router is programmable from 1,250 - 24,000 RPM, RH or LH rotation.(1) 10-Position ATC rack located at the end of machine. -- Operator InterfacePC Front-End with: WEEKE "PC 85T" + "Windows XP" + WoodWOP Operating System.17" TFT Color graphic monitor; keyboard for data entry; PC 85T hand control pendant; central USB hub; Ethernet interface for LAN connection to office PC; RS-232 serial interface.BECKHOFF Programmable logic control for (3/4) axes, linear, circular & helical interpolation; the controller is contained in a separate freestanding, dust-free control cabinet that can be placed at either the LH or RH side of the machine. -- Complete with: (4) 100 cbm/Hr Vacuum Pumps; safety light curtain (the machine will stop when the Operator enters the work area); safety fencing; separate control cabinet. - Manuals & Documents -- Options Include: NC Controlled Touch-Off Tool Probe, length measuring device. (1) NC controlled scissor lift/vacuum in-feed device. (1) NC controlled, powered flat belt outfeed table with Automatic Dust Control Vacuum Sweep Arm Rake system. Laser fence surround for safety -- Actual Model is: WEEKE VANTECH 512 CON2/BHP 008.

$59,500

WEEKE BHP 100/VANTAGE 480 FLAT TABLE MACHINE, with ATC, Boring, Infeed Roller & Outfeed & 4,771 Hrs. (As of 10/31/23) -- Specifications:4' x 8' Bridge style gantry machine with User-Friendly "S/C Tech" "MATRIX" grooved phenolic vacuum table. -- Working Area:'X" axis 99.21" (2,520 mm), "Y" axis 49.21" (1,250 mm), Max. material thickness of 3.94" (100 mm). -- Travels:“X"; axis 146.06"; (3,710 mm), “Y"; axis 81.30"; (2,065 mm), “Z"; axis 13.70"; (348 mm) Routing, 8.46"; (215 mm) Boring. -- Positioning Speed:"X" & "Y" axis Vector speed is 314 FPM (96 MPM), "Z" axis 65 FPM (20 MPM);The head travels via AC brushless drives & THK linear motion guides on all axes. -- Worktable:User-Friendly "S/C Tech "MATRIX" grooved phenolic vacuum table for easy vacuum pod placement.(2) Fixed LH side & (2) Fixed RH side pneumatic pop-up positioning stops. -- Boring Unit:(1) 3 HP (2.3 kW) Motor, variable speed for 1,500 - 7,500 RPM;(21) Independent vertical spindles with (8) in "X" axis, (9) in "Y" axis (1st Row), & (4) in "Y" axis (2nd Row). -- Machining:(1) 12 HP (9 kW) Air Cooled High speed constant duty Router with HSK F63 adaptor,1,250 - 24,000 RPM, constant torque achieved at 9,000 RPM, RH or LH rotation(1) 14-Position tool changer Carousel located at the back side of the spindle carriage. -- Machine & Operator Control:PC Front-End with WEEKE "Power Control + Windows + WoodWOP operating system.17" TFT Color graphic monitor, Hand-held control pendant, Foot pedal control;"BECKHOFF" Programmable logic control for (3/4) axes, linear, circular & helical interpolation;The controller is contained in a separate free-standing, dust-free control cabinet that can be placed at either the LH or RH side of the machine. -- Complete with: 488"; W x 96"; L Infeed electric/hydraulic Scissor Lift platform, with 3"; x 3"; Support beams on 7"; Centers; 4’ L Roller track intermediate table; vacuum arm with (2) 10"; dia. vacuum pads; rake off-feed System; 49"; W x 10’ L x 36"; H Outfeed motorized belt conveyor; BUSCH "MM 1322 A VM3" 10 HP (7.6 kW) 300 mbar Vacuum Pump; 6’ H Safety fencing. -- Actual model is WEEKE BHP 100/VANTAGE 480Machine Dimensions: 292"; x 202"; x 96"; H.Machine with Scissor Lift Dimensions: 389"; x 202"; x 96"; H.

Call for Price

WEEKE VANTECH 510 V7 PO FLAT TABLE MACHINE (LOADING & UNLOADING): -- Specifications:5' x 10' Flat Table "Bridge Gantry" machine with User-Friendly "S/C Tech" "MATRIX" grooved phenolic vacuum table. -- Working Area:"X" Axis is 122" (3,100 mm), "Y" axis 61" (1,550 mm), "Z" axis stroke is 9.6" (243.8 mm), max. material thickness of 3.9" (100 mm). -- Positioning Speed:"X" Axis is 236 FPM (72 MPM), "Y" axis is 203 FPM (62 MPM), "Z" axis 82 FPM (25 MPM).The head travels via AC brushless drives & THK linear motion guides on all axes. -- Worktable: User-Friendly "S/C Tech MATRIX" grooved phenolic vacuum table for easy vacuum pod placement.(2) Pop-up Pneumatic locator/positioning bars, one on each side in "X" axis & (1) Pop-up pneumatic locator/positioning pins in "Y" axis.(4) Vacuum Table work zones can be used independently or together for full table area Foot pedal vacuum zone controls. -- Machining:(1) 16 HP (12 kW) High speed electro-spindle router with "HSK F 63" adaptor; constant duty, variable speed from 1,250 - 24,000 RPM, RH or LH rotation.(1) 8-Position ATC rack located at the end of machine. -- Operator Interface:PC Front-End with WEEKE "PC 85T" + Windows "7" + WoodWOP operating system.17" TFT Color graphic monitor, keyboard for data entry, PC 85T hand control pendant; central USB hub, EtherNET interface for LAN connection to office PC, RS-232 serial interface, "BECKHOFF" Programmable logic control for (3/4) axes, linear, circular & helical interpolation; the controller is contained in a separate free-standing, dust-free control cabinet that can be placed at either the LH or RH side of the machine. -- Complete with:(2) 225 m³/Hr Vacuum pumps; safety light curtain (the machine will stop when the operator enters the work area), safety fencing, separate control cabinet. -- Options Include: Boring unit with 2 HP (1.5 kW) motor & (7) Independent vertical spindles with "Quick Change" drill bit holders; programmable variable speed from 1,500 - 7,500 RPM; Touch-off tool length measuring device (1) SCHMALZ "Jumbo Ergo 85" Vacuum Lift (1) NC controlled, powered flat belt outfeed table (1) Automatic Dust Control Vacuum Sweep Arm/Rake system. -- Actual Model is WEEKE VANTECH 510 V7 PO