704-841-2001

Backed with a massive machinery database considered to be “the blue book” of woodworking machinery), EX-FACTORY Auctions provides a complete assessment of your equipment and allows you to interact with the market real-time in our dynamic Online Auction!

2105 Results Found

704-841-2001

$15,075

JLT CLAMPS 718A-12-M Panel and Door ClampBuddy System includes #79F-12-PC & #717AUnique all-in-one Panel Clamp & Cabinet Door Clamp. -- The DDC has a larger clamping area of 38" Deep x 98" Wide with a splitter for two (2) door clamping. -- Double door design, air operated assembly clamp specifically designed for entry doors, cabinet doors or windows. -- (2) Heavy Duty quick adjusting pneumatic clamping cylinders & (1) quick adjusting cross-clamp on the side. -- (1) Quick adjusting cross-clamp for the rails with (3) draw clamps for the stiles. -- 2" Deep squaring fence along left and bottom sides. -- Single-lever cylinders for quick & accurate clamping pressure. -- Shelf area to hold the pieces of the frame prior to clamping for all squaring components. -- 5-Tier self-supporting rack unit; each tier is 12' wide; total of (18) clamps on the rack. -- 32" or 40" Opening clamps available; must be specified when placing order. -- Clamps with 2-1/2" high jaws and manual movement & tightening. -- Additional clamps are available. -- 40 Sq. ft. footprint.

JLT CLAMPS 79F-8-PC Panel and Door Clamp. An Industry standard for Cabinet doors and so much more. -- (5) Levels of 8' wide x 40" deep cap. -- Heavy tubular frame with (18) clamps. -- Manually adjustable bar clamps that easily set in place and move from side-to-side. -- 40" Clamp opening with a 3-1/2" high x 4" wide jaw. -- Additional opening clamps available.

JLT CLAMPS 79F-6-PC Panel and Door ClampAn Industry standard for Cabinet doors and so much more. -- (5) Levels of 6' wide x 40" deep cap. -- Heavy tubular frame with (8) clamps. -- Manually adjusted bar clamps that easily set in place and move from side-to-side. -- 40" Clamp opening with a 3-1/2" high x 4" wide jaw. -- Additional clamps are available.

$2,275

JLT CLAMPS 138B Glue ApplicatorPlate type glue applicator with 8" wide x 48" long applicating capacity. -- Spreader frame is constructed of heavy perforated aluminum components. -- All glue application components such as the grid, glue pan and cover are constructed of steel. -- Foot treadle operated and the grid rises out of the reservoir of glue. -- The thickness of the glue is easily regulated by the operator. -- No daily clean-up is required, simply spray the surface of the glue with water and cover the unit for overnight storage. -- Several depressions of the foot treadle mixes the glue and can thin the glue when water is added.

$10,975

JLT CLAMPS 79K-10 Panel and Door Clamp; Versatility-Leave the center squaring bar to do multiple doors at once or remove the bar to take advantage of the full capacity of the machine. -- Capacity for solid wood doors 48" x 120". -- Quick release latches on the jaws and moveable squaring bar. -- The squaring mechanism can be re-calibrated if necessary. -- (2) Horizontal pneumatic clamps. -- (4) Vertical pneumatic clamps. -- One lever operation. -- 1000 Lbs of clamping force per cylinder. -- 3" Stroke from each cylinder.Custom sizes available in 1' increments ...ask the Product Manager.

JLT 717C-DC Cabinet Door Clamp:Pneumatically operated Cabinet Door Clamp to square & clamp door in (1) Second. -- 26" Front-to-back x 62" left-to-right clamping capacity. -- Single row door clamp with (1) horizontal pneumatic clamp & (2) vertical pneumatic clamps. -- Special mount on a 30° angle for ease of loading & less operator fatigue. -- (3) Large diaphragm cylinders for quick clamping pressure with single lever operation. -- 40 PSI Air pressure to produce 500 Lbs of force on each clamp. -- Shelf to hold the pieces of the frame before pressing on all squaring components. -- 40 Sq. ft. floor space requirement.(Replaces: #717A-DC)

JLT CLAMPS 717C-M Panel and Door ClampPneumatically operated Cabinet Door Clamp to square & clamp a door in (1) Sec. -- 26" Front-to-back x 62" left-to-right clamping cap. -- Special design for mitered doors. -- Single row Door Clamp with (2) horizontal pneumatic clamp & (2) vertical pneumatic clamps. -- Special mount on a 30° angle for ease of loading & less operator fatigue. -- (4) Large diaphram cylinders for quick clamping pressure with single lever operation. -- 40 PSI Air pressure to produce 500 Lbs of force on each clamp. -- Shelf to hold the pieces of the frame before pressing on all squaring components. -- 40 Sq. ft. footprint.(Replaces #717A-M)

JLT CLAMPS 717C-M1-DDC CLAMP, PANEL AND DOOR.Pneumatically operated Cabinet Door Clamp to square & clamp a door in (1) Sec. -- 38" Front-to-back x 98" left-to-right clamping capacity. -- Single row 2-station Door Clamp with (2) horizontal pneumatic clamps and (4) vertical pneumatic clamps. -- Special mount on a 30° angle for ease of loading & less operator fatigue. -- (6) Large diaphragm cylinders for quick clamping pressure with single-lever operation. -- 40 PSI Air pressure to produce 500 Lbs of force on each clamp. -- Shelf to hold the pieces of the frame before pressing for all squaring components. -- 60 Sq/ft footprint.(Replaces #717A-DDC)

JLT 79F-12-PC Panel and Door Clamp An Industry standard for Cabinet doors that offers so much more. -- (5) Levels of 12' width x 40" depth cap. -- Heavy tubular frame with (6) clamps per level x (5) levels for a total of (30) clamps. -- Manually adjusted bar clamps that are easily set in place and can move from side-to-side. -- 40" Clamp opening with a 3-1/2" high jaw. -- Additional clamp openings available.

JLT CLAMPS BUDDY 718A-8 Panel and Door Clamp Unique all-in-one Panel Clamp & Cabinet Door Clamp.Specifications: -- 26" Deep x 62" wide clamping cap. -- Single row door clamp, air operated assembly on a 70° angle for entry doors, cabinet doors or windows. -- (2) Heavy Duty quick adjusting pneumatic clamping cylinders. -- (1) Quick adjusting cross-clamp for the rails with (3) draw clamps for the stiles. -- 45° Working angle for easy access & less fatigue. -- 2" Deep squaring fence along left & bottom sides. -- Single lever cylinders for quick & accurate clamping pressure. -- Shelf area to hold the pieces of the frame prior to clamping for all squaring components. -- 5-Tier self-supporting rack unit; each tier is 8' wide; total of (18) clamps on rack unit. -- 32" or 40" Opening clamps available; must be specified when placing order. -- Clamps with 2-1/2" high jaws with manual movement and tightening. -- 40 Sq. ft. footprint.

$12,300

JLT CLAMPS 718A-12 Buddy System Panel and Door ClampBuddy System includes #79F-12-PC & #717AUnique Panel Clamp & Cabinet Door Clamp all-in-one. -- 38" Deep x 98" wide clamping cap. -- Air operated assembly, single row Clamp on a 70° angle specifically for entry doors, cabinet doors or windows. -- (2) Heavy Duty quick adjusting pneumatic clamping cylinders. -- (1) Quick adjusting cross-clamp for the rails with (3) draw clamps for the stiles. -- 45° Working angle for easy access & less fatigue. -- 2" Deep squaring fence along left & bottom sides. -- Single lever cylinders for quick & accurate clamping pressure. -- Shelf area to hold the pieces of the frame prior to clamping for all squaring components. -- 5-Tier self-supporting rack unit; each tier 12' wide for a total of (18) clamps. -- 32" or 40" Opening available; must be specified when placing order. -- Clamps with 2-1/2" high jaws with manual movement and tightening. -- Additional Clamps available. -- 40 Sq. ft. footprint.

JLT 190B-M3 Drawer Clamp. Heavy-duty Drawer and Box clamp, maximum capacity 10" H x 24" L x 36" W Specifications & Features: -- Achieve 3,000 Lbs. clamping force at 100 PSI air pressure. -- Easy to use mounted lever valve with intergraded pressure hold kit. -- Pneumatic foot pedal activation. -- 2- Clamp Design provides equal pressure from top to bottom. -- Horizontal aluminum side pressure walls offer a non-marking smooth durable surface. -- Fast, easy changeovers with minimal adjusting. -- The vertical clamping carriage slides smoothly for horizontal width adjustments.Complete with: -- (3) Sets of pressure shoes for added strength also eliminate vertical (drawer depth) adjustments. -- (1) Set of aluminum side plates. -- (1) Lever valve pressure hold kit.

$10,950

JLT CLAMPS 79F-16-PC Panel and Door Clamp. This Clamp for the Custom Woodworker who produces 16' Railing, Long Posts and Face Glue Solid Wood Components up to 6" thick. -- (3) Levels of 16' long x 52"wide x 70" high -- Heavy tubular frame with (36) # 302-40-H-R 3.5" high Jaw 40" Taylor Clamps. Made of solid steel and are manually tightened with a JLT "T" handle. -- Manually adjustable bar clamps that easily set in place and move from side-to-side. -- Heavy Duty Construction with 5000 Lbs. capacity. Great for the big jobs. -- Clamps are aligned perfectly for a straight and precise clamp face. -- 6" High rocker adapter Plates offer consistent clamping pressure throughout the glue joint. -- -- JLT heavy duty clamps offer up to 3000 Lbs of clamping pressure. -- JLT Clamps are guaranteed Never to twist, bow or bend! -- Clamping System Package Includes: (1) #79F-16-PC 16' long multi-level panel clamp. -- (36) #302-40-H-R 3.5" High jaw 40"opening Taylor Clamps. -- (72) #80-1706 Gocker adapter plates for up to 6" thick glue ups. -- (1) Fastener and shim kit for precise clamp alignment.

$10,350

JLT CLAMPS 190C-M2 Drawer Clamp Heavy-duty Upper Box and Case Clamp, maximum capacity 12" H x 48" L x 48" W -- Achieve 3,500 Lbs clamping force at 100 PSI air pressure. -- Easy to use mounted lever valve with intergrated pressure hold kit. -- Pneumatic foot pedal activation. -- (4) Clamp Design provides equal pressure from top to bottom. -- Horizontial aluminum side pressure walls offer a non-marking smooth durable surface. -- Fast, easy changeovers with minimal adjusting. -- Vertical clamping carriage slides smoothly for horizontial width adjustments. -- (5) Sets of pressure shoes for added strength also eliminates vertical (drawer depth) adjustments. -- Includes: (1) Set of aluminum side plates, (1) lever valve pressure hold kit.

Call for Price

LOCATELLI "OMK-300" Automatic Lathe with Sanding; From automatic feeding to finished product ejection - a complete "Turning & Sanding" System. -- 11-13/16" Max. between centers, 3-1/8" max. & 5/16" min. stock dia., 5.5 HP spindle motor with (3) spindle rotations of 3,020 - 4,580 & 6,400 RPM.6-Station Rotary Carousel/Drum with the following operations: -- Station 1: Pickup and centering of workpiece. -- Station 2: Turning with hydraulically operated roughing & finishing gouge. -- Station 3: Finish turning with hydraulically operated finishing gouge; rough & finish gouges advance via 1.5 HP hydraulic motor at a rate of 0.33 - 52 FPM. -- Station 4: Initial sanding with adjustable 0.5 HP vibrating brush. -- Station 5: Secondary sanding with adjustable 0.5 HP vibrating brush. -- Station 6: Ejection of finished workpiece. -- PLC Function for immediate fault detection and facilitates setup. Complies with CE high standards for operator safety. -- Features: Billet capacity has been increased to a special 5.9" x 5.9" (150 mm square). -- Complete with: Separate operator control panel. -- Includes: Inventory of spare parts and tooling. -- Machine kept under power but has not been used for production for several years.

LOEWER DENIBBING SANDER4-Head, 53" width cap., great Denibbing Sander -- The patented conbination of rollers and rotating / oscillating discs makes the Perfection BBDD sanding machiine the ideal finishing solution for entry doors, cabinet doors, drawer fronts, sheet foods, shutters, face frames, furniture and much nore. -- The LOWER DMBBDD sanding machine is sthe ideal soluton for all sanding applications including whitewood, stain and sealer coats(inciuding UV). The work piece first passes under two large counter rotating spiral hubs, then under eleven rotating discs that oscillate from left to right. This provides very uniform edge breading in whitewood sanding and eliminates most (if not all) hand sanding of the sealer coat. -- The patented combination of roller and rotating discs provieds very uniform sanding across the entire work piece, even into deep profiles without loosing detail. -- SPECIFICATIONS OF MACHINE --Thickness of work piece Min: 10mm (1/2")-- Max: 80mm (3") --Feed belt width Max:1350mm (53") --Feed belt motor 1.5 KW (3Hp) 3-15 M/min (10-50 Ft/min) --Top sanding roller 2.2KW (3Hp) 25-300 O/min (RPM) --Disc Rotation 2.2KW (3Hp) 25-300 O/min (RPM) --Disc Osciliatiojn ).37KW (0.5) 10-60 O/min (RPM) --Vacuum motor 7.5KW (10Hp) --Machine weight 1,800 kg -- Aproximate Machine dimensions based on similr machine W:2000mm (6'7")/ L:2780mm (9'2")/ H:6'11")

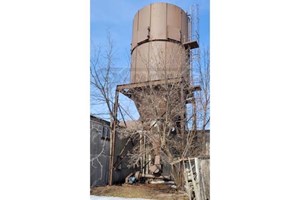

Dust Collection Pipe (Snap Ring type Pipe)Quantity - Diameter - Length Description(2) 22" - 12" - 38" Branch.(1) 24" - 12" - 38" Branch.Many loose Snap Rings in the tote.(1) 25" - 59" Pipe.(4) 22" - 59" Pipe.(2) 24" - 59" Pipe.(1) 24" x 22" x 6" 21"; Reducer with branch.(1) 22" x 20" x 12" 33"; Reducer with branch.(1) 11" x 10" x 10" 29"; Reducer with branch.(1) 12" Auto gate.(18) 10" - 59" Pipe.(2) 9" - 59" Pipe.(1) 11" - 59" Pipe.(4) 12" - 59" Pipe.(1) 22" - 29" Pipe.(1) 20" - 50" Elbow.(1) 20" x 16" x 12" - 33" Reducer with branch.(1) 24" x 24" x 10" - 29" Branch.(1) 24" x 24" x 6" - 24" Branch.(1) 16" x 12" x 7" x 7" - 45" Reducer with branch.(1) 22" x 22" x 6" - 20" Branch.(7) 12" - 59" Pipe.(4) 14" - 59" Pipe.(1) 16" - 43" Pipe adj.(18) 8" - 59" Pipe.(68) 6" - 59" Pipe.(10) 3" - 59" Pipe.(2) 8" - 32" Pipe.(32) 8", 9", 10", 11" - 59" Pipe.(46) 5" - 59" Pipe.(8) 7" - 59" Pipe.(39) 4" - 59" Pipe.(1) 14" x 12" x 6" - 21" Reducer & branch.(1) 14" x 14" x 6" - 21" Branch.(20) 3", 4", 5", 6" - Various pipe. (1) 6" x 6" x 6" - 21" Branch.(1) 10" x 10" x 4" - 17" Reducer.(1) 10" x 7" x 7" - 23" Reducer.(1) 10" x 9" x 4" - 17" Reducer & branch.(1) 10" x 7" x 7" - 23" Reducer & branch.(1) 10" x 7" 9" Reducer(5) 10" - 18" 90° Elbows.(20) 5" - 8" 90° Elbows.(7) 7" - 8" 90° Elbows.(23) 6" - 8" 90° Elbows.(20) 8" - 20" 90° Elbows(4) 5" - 6" Saddle.(1) 7" x 4" x 4" - 19" Reducer & branch.(2) 8" x 7" x 6" - 21" Reducer & branch.(1) 7" x 6" x 4" - 17" Reducer & branch.(1) 11" x 11" x 9" - 31" Branch.(1) 12" x 8" x 8" - 19" Reducer & branch.(1) 7" x 6" x 5" - 19" Reducer & branch.(1) 11" x 10" x 4" - 17" Reducer & branch.(1) 14" - 39" - 90° Elbows.(1) 9" - 20" 90° Elbows.(2) 10" - 16" 90° Elbows.(1) 7" 22" Pipe.(1) 10" x 10" x 4" - 17" Branch.(2) 10" x 8" x 6" - 21" Reducer & branch.(1) 14" - 39" 90° Elbow.(1) 9" - 20" 90° Elbow.(2) 10" - 16" 90° Elbows.(1) 7" - 22" Pipe.(1) 10" x 10" x 4" - 17" Branch.(2) 10" x 8" x 6" - 21" Reducer & branch.(1) 8" x 8" x 6" - 23" Branch.(1) 12" x 10" x 6' - 21" Reducer & branch.(1) 8" x 6" x 4" - 18" Reducer & branch.(28) 4", 5", 6", 7", 8", 9", 10", 14" Misc.(1) 14" x 11" x 6", 6" 42" Reducer & branches.(1) 8" x 7" x 6" - 21" Reducer & branch.(1) 12" x 7" x 7" - 34" Reducer & branch.(1) 12" x 11" x 4" - 17" Reducer & branch.(1) 5" x 5" x 5" - 17" Branch.(1) Batch 50' - 24" Straight pipe.(1) Batch various 24" - 90° elbow.(1) Batch various 24" - 45° elbow.(1) Batch 150' - 12" Straight pipe.(1) Batch various 12" various fitting.

Call for Price

MAC 120-MCF-572 High Capacity Baghouse Dust Collection system with Rotary Air Lock (RAL) and Medium-pressure Controlled air cleaning dust Filter (MCF). -- Baghouse Capacity: 50,000 CFM @ 7.2:1 Air-to-cloth ratio (ACR), approx. 6,921 sq-ft of filter area based on (572) Filter bags; 120" long x 5" dia. -- Equipped with: (1) AIR TECH size 402, BISW, Backward Inclined Air Handling Fan, Class IV, with 40" inlet, ground-mounted on unitary base, flanged inlet box & outlet. For prior application fan operating point (RPM/SP) is set up for about 41,526 CFM @ 12" WG at 1566 RPM, drawing 119 BHP. the fan is equipped with a variable volume damper on discharge. Fan range is about 40,000 - 55,000 CFM. Powered by a TOSHIBA 150 HP TEFC, 444T, 1800 RPM motor packaged with a belt drive -- Bag Cleaning: Mac "Never-Miss" Cleaning System with rotating arm, diaphragm valve for pulse cleaning Approx. 3 HP positive displacement (PD) pump for bag cleaning at only 7- 9 PSIG. 1 HP direct drive gear motor for distribution arm, integral manifold/surge tank, pneumatically controlled firing mechanism activating the diaphragm valves/nozzles. When cleaning arm & bag segments are correctly aligned air nozzles fire directly into bags without wasted cleaning air. -- Includes: MAC FS24x24 AIRLOCK Rotary Air Lock (RAL) with approx. 2 HP SYNCROGEAR MODULE gear motor; sprinkler package; 60° Cone-shaped hopper attached to MAC at bottom of cone. -- Features: Floor-standing Electrical controls (excluding shared controls) with MOTORTRONICS Solid State AC Softstart for main 150 HP motor. -- Additional Features: Explosion vents. Summer/Winter diverter and return air ductwork. Support structure. Caged access ladder from ground Service Platform and to the top plenum. -- Baghouse constructed of 7 gauge carbon steel containment; one piece body all welded construction, 180" (15') diameter shell panelized unit, walk-in plenum for maintenance and bag replacement. -- MAC design features: MCF 4HVP Pump package. MCF Medium-pressure air requires less HP and yet offers high dust and air collecting efficiency with unmatched baghouse cleaning at lower operating cost. MCF pulses each bag the same number of times with the same amount of air. (Unlike some competitors which clean the inside rows of bags more often than necessary thus wasting energy, causes uneven pressure drop, and bag wear). -- (2) of these identical units are installed per photos, one only is available based on Owner/buyer agreement and price point. Material handling fan/drive is not included and is assumed to stay with the remaining filter unit. -- Overall dimensions: 580.5" high x178.5" square frame with an estimated weight of filter unit (less structure and accessories) 31,000 Lbs. -- Professional dismantling/rigging, truck loading and transportation are available at extra cost. -- NOTE: Per photo #1 on the Ex-Factory website the unit for sale is on the right-hand side. The left-hand unit is not easily accessible.

Call for Price

MAC/SCHENCK 144-RPT-252 STYLE III Baghouse Filter System with Pulse Jet Cleaning and Rotary Air Lock (RAL) discharge.RPT Filters (Rectangular Pulse Top-Removal) Rectangular top removal bodied filter unit designed to handle high air volumes. • Bags are removed vertically from the top clean section. Walk-in plenum so the filter media replacement and maintenance can occur in an enclosure for inclimate weather. -- Baghouse Capacity: 4,770 sq. ft. of cloth consisting of (252) bags, 144" long 16 Oz P84 Top Load bags and bright wire cages. Depending on your application, for example at an air-to-cloth ratio of 3.14:1 it can develop 15,000 CFM. -- Equipped with: (1) PHELPS FAN, Material Handling, WRM-380 CCW-TAU HD ARR. 8 with A-36 inlet flange Performance at 15,000 ACFM & 15" SPWG, 1780 RPM, 315°F, 0.050 #/cu. ft..500' elev. Direct drive MOTOR IS NOT INCLUDED but was designed for 75 HP, 1800 RPM,, 365T. Fan was connected in a negative pressure configuration, flanged inlet & outlet. -- Bag Cleaning; Requires 33 SCFM of clean, dry air at 90-100 PSIG. -- Complete with: Auger on bottom of hopper feeding Rotary Air Lock (RAL) with approx. 1.5 HP gearmotor at 22 RPM.; (3) Rupture style explosion vents.. -- Features: Equipped for High Temperature (400°F) bags Special equipment includes VITON Diaphragm valves, copper line (in lieu of polyflo tubing)high temperature air header connections and hi-temp purge pipe compression on couplings. (2) 2" NPT couplings with plugs are included in the plenum section for future addition of sprinkler/deluge system. -- Filter unit constructed of carbon steel containment with 3/8" x 4" reinforcing ribs. 34" diam. high entry inlet and top outlet. -- Includes: Nema 4 Timer Board and solenoid valve enclosure. Each require 110/60 Hz power supply. Filter has (2) solenoid valve enclosures. -- Dimensions: 492" overall height (ground to top), 156" square sides. Separates into (3) sections: Top Plenum, filter section and bottom hopper/support steel. -- Dismantling/rigging is included. Please inquire for transport to your location.. -- NOTE: Extra high Stainless Steel stack is available if you want it.

Call for Price

MACDONALD STEEL 65 ST Dust Collector System with Shaker filter cleaning, Rotary Air Lock, and 18' dia. housing. -- Specifications: Capacity for 65,000 CFM, 18' dia. shell, with 8,199 sq-ft. of filter area for an air-to-cloth ratio of 7.7:1. T-150 polyester bags 14 oz. with a 30 - 40 CFM.@ 1/2" WG permeability. -- Current Fan configuration: System 1: Fan inlet of 33" at 32,500 CFM; System 2: .Future capacity for a second fan as per System 1. Return air duct is 42" x 72". -- Filter Cleaning: Top mounted electrically operated & timed mechanical shaker, approx. 2 HP motor which will automatically operate on all shutdowns. -- Equipped with: MACDONALD 18" Rotary Air Lock (RAL) with bottom eductor/T-section for connection to a relay/transfer fan (not included.). -- Complete with Fire Damper, Summer/Winter Damper with Silencer, Explosion doors, safety ladders, and access platform. -- Features: 13" MH/HT 20 HP Transfer/Transport fan -- Overall height is currently 57'-3" with 12' clearance under RAL. Weight of filter with structural steel is 29,000 Lbs plus fan is about 3,000 Lbs. -- Shell panelized construction (made of separable panels allowing for road/Hwy travel).Professional rigging, loading and transportation are available at extra cost; quote upon request.