Boring Machines For Sale

Category

Boring Machines

101 Results Found

Call for Price

MORBIDELLI AUTHOR 504 R CNC MACHINING CENTER (W/ATC/BORING): -- Specifications: Working Cap. "X" Axis 139-3/8" (3,540 mm); "Y" axis 48-3/8" (1,230 mm) for routing & 39.6" (1,008 mm) for boring; "Z" axis 3.1" (80 mm). -- Positioning Speed:"X" Axis 213 FPM; "Y" axis 131 FPM; "Z" axis is 65 FPM. -- Worktable:(8) Adjustable panel supports each with: (3) Vacuum pods; worktable setup for (2) independent working areas. -- Boring Unit:(29) Independent vertical boring spindles forming a T-configuration with: (15) Spindles on the "X" axis and (14) spindles on the "Y" axis.A total of (8) horizontal spindles with: (3 + 3) on "X" Axis; (1 + 1) on "Y" axis. -- Machining:(1) 9 HP (7 kW) Vertically mounted router; inverter driven (FUJI) at 12,000 - 18,000 RPM.(1) 8-Position ATC for Automatic Tool Changer. -- Operator & Machine Control:"NUM CN" Loaded onto a HP, PC Based Controller mounted in separate control cabinet.15" VGA Color monitor and ergonomic keypad. Remote Control Pendant: Allows the operator to move around and still control all the axis movements, speed, and emergency stop.Includes: USB Ports; (2) serial ports RS-232 & RS-242 (requires no 3rd party CAD system for downloading programs). XILOG-PLUS OPERATOR Interface: Offers incredible list of: Functions from (a) Auto. diagnostic to (z) zooming; controlled acceleration & deceleration, encoder feedback, dynamic tool correction via PLC due to active tool wear using space-and-time criteria; programs can be transferred via diskette or downloaded by wire. Equipped with: Onboard mini-CAD with built-in programming for writing circles, ellipses & angles with only a few keystrokes; on-board cycle optimization, on-board calculator, mirror imaging, and repeat imaging. -- Complete with:(1) 100 cbm/Hr Vacuum Pump. -- Actual model is: MORBIDELLI - Author 504 .

$ 17,000

MORBIDELLI U 550 CNC MACHINING CENTER (W/ATC/BORING): -- Specifications: Worktable area "X" axis 126" (3,200 mm); "Y" axis 51" (1,300 mm),;"Z" axis stroke 4.52" (115 mm); max. material thickness 3.1" (80 mm). -- Positioning Speed:"X" & "Y" Axes are192 FPM (58 MPM); "Z" axis 80 FPM (24 MPM). -- Worktable:(8) Adjustable panel supports with (3) vacuum pods per support.(8) Pneumatic backstops, (2) pneumatic side stops & (2) pneumatic center stops; (2) independent work zones. -- Boring Unit:(1) 4 HP (3 kW) - 4,000 RPM Motor; (29) independent vertical spindles at 32 mm centers with (14) vertical spindles in "X" axis & (15) vertical spindles in "Y" axis.(6) Horizontal spindles with (3 + 3) in the "X" axis. -- Machining:(2) 9 HP (6.7 kW) Routers with: ISO 30 Adaptors; variable speed from 12,000 - 18,000 RPM.(1) 5-Position tool racks mounted on the LH side of the machine base for ATC. -- Operator & Machine Control:Separate control cabinet with: "TRIA 7500" CNC 32-Bit multiprocessor (100% MS/DOS compatible), 512 KB user RAM.14" VGA Color monitor; ergonomic extended keypad with (18) function keys; 1.44 MB floppy disk drive & (2) RS 232 & (1) RS 242 serial ports. -- Complete with:(1) 100 cbm/Hr Vacuum Pump; working head safety enclosure; emergency stop rope. -- Actual Model is: MORBIDELLI - U 550.

$ 17,000

MORBIDELLI U 550 CNC MACHINING CENTER (W/ATC/BORING): -- Specifications: Worktable area: "X" Axis 126" (3,200 mm); "Y" axis 51" (1,300 mm); "Z" axis stroke 4.52" (115 mm); max. material thickness 3.1" (80 mm). -- Positioning Speed:"X" & "Y" Axis are 192 FPM (58 MPM); "Z" axis 80 FPM (24 MPM). -- Worktable:(8) Adjustable panel supports with (3) vacuum pods per support.(8) Pneumatic backstops; (2) pneumatic side stops & (2) pneumatic center stops; (2) independent work zones. -- Boring Unit:(1) 4 HP (3 kW) - 4,000 RPM Motor; (29) independent vertical spindles at 32 mm centers with: (14) Vertical spindles in "X" axis & (15) vertical spindles in "Y" axis.(6) Horizontal spindles with (3 + 3) in the "X" axis. -- Machining:(2) 9 HP (6.7 kW) Routers with: ISO 30 Adaptors; variable speed from 12,000 - 18,000 RPM.(1) 5-Position tool rack mounted on the LH side of the machine base for ATC. -- Operator & Machine Control:Separate control cabinet with: "TRIA 7500" CNC 32-Bit multiprocessor (100% MS/DOS compatible); 512 KB user RAM,14" VGA Color monitor; ergonomic extended keypad with (18) function keys; 1.44 MB floppy disk drive & (2) RS 232 & (1) RS 242 serial ports. -- Complete with:(1) 100 cbm/Hr Vacuum Pump; working head safety enclosure; emergency stop rope. -- Actual Model is: MORBIDELLI - U 550.

Call for Price

Single horizontal drill and dowel; 1300 mm work table with four fields; sure shot revolver system to guarantee the fastest cycle time, average one second, and extreme reliability; simple user friendly touch screen; heavy duty steel frame for maximum rigidity; large phenolic table with robust clamps suitable also for delicate materials; barcoding and ethernet ready; laser for measuring the part and populate the program;

Call for Price

RILESA UNI-X 2200 FEED THUR CNC BORING MACHINE W/4-SIDE DRILLING, in one pass. -- Specifications:Working Capacity; 230 mm - 2,200 mm (9' - 86.6") Length, 20 mm - 250 mm ((0.78" - 9.84" width, 10 mm - 60 mm (0.39" - 2.36") thickness.Capacity: up to 900 parts/hour without cross drilling. -- Features:One-man operated. 4-side drilling, in one pass. With Rilesa UNI-X drilling machine you get precision, quality and extreme high capacity. It is well suited to both small and large dimensions. It has short set up time and minimal maintenance. -- Polyurethane an guides ensure gentle handling of components. The restraining clamp automatically adjust to component width ensuring correct location to the zero point. -- The drilling boxes are designed for high speed drilling, 4500 RPM. The tool inserts can be chosen Between direct or snap assembly. Special drill boxes can be manufactured to specific customer requirements. -- Assembly of drill boxes takes place with a snap function and is simply locked with screw. The drill box can be freely turned between 0 and 90°. In the outer positions there are stops. -- The drill groups unique design gives a high degree of adjustment flexibility. The center distance between groups is 95 mm. Pneumatic over hydraulic drill feed. Drill speed, 4000 RPM. -- The components are fed in pneumatically up to the reference stop and locked securely in this position. A unique safe regulated system makes sure the component is in place without pressmark. -- The operator uses signal lamps to make adjustments. The operator manually moves the drill groups into position checking the lights. Yellow to green = Tolerance. -- The machine closed design with built in dust extraction gives the perfect place to work. Notice the sturdy construction of the machine body. -- Loading of components is very easy by pushing the stack in through the brushes. The machine components are transported gently back to the operator. The conveyer can run continuously or in step mode. -- For long components support elements can easily be added. They are located with a simple clamp and ensure straightening of the workpiece. -- The machine can be delivered with sideways displacement of the drilling group. The drilling group displace up to 100 mm, this function combined with programming of the drilling, do difficult drilling in one passage, possible. -- The control system is integrated in the back of the machine, well protected against dust. There is room for future expansions to be added. -- Hopper / Magazine:Pneumatic magazine with ergonomics and user friendly access. Automatic fixation to the zero point by a pneumatic counter clamp with polyurethane and nylon covering for careful handling of the component. -- Return conveyor with an adjustable catcher tray, build-in clamp cylinder mounted at each end, for flexible and safe clamping of the components, adjustable catcher tray. -- Operator Interface:Advanced 15"; color TFT touch screen control system where

$ 4,250

RITTER R-26 Boring Machine (2-Head Line Boring)(2) 13-Spindle belt driven drill heads, drills from the top down, each head with 2 HP - 3,450 RPM motor; both heads with rack & pinion adjustment 4" min. to 24" max. spacing. -- Spindles on 2" centers, 10 mm collets; 30" x 48" table, table cycles up/down with a 3" stroke. -- Equipped with: (2) Adjustable stops, (2) spring hold-downs on the rear head; and foot pedal actuated boring cycle.

Call for Price

This machine has been cleaned, repaired and checked over, ready for a new home! (2) 3HP motors 460V 3Ph 6 pneumatic stops for use in horizontal or vertical drilling 72" precision machined back fence 6 fence stops, 4 table stops (2) 23-spindle drilling heads, one horizontal, one vertical 3-position turret dept stop on vertical head 5 pneumatic holddowns Magnetic motor controls 32mm spindle centers 10mm collet diameter 1725 RPM spindle speed 90 PSI air requirement 3" max. drill stroke

$ 15,000

SCM TECH Z 30 CNC MACHINING CENTER (W/ATC/BORING): -- Specifications:Working Field "X" axis 120" (3,050 mm); "Y" axis 52.7" (1,340 mm) for routing & 44" (1,118 mm) for boring; "Z" axis stroke 7.8" (200 mm); max. material thickness 3.9" (100 mm). -- Positioning Speed:"X" & "Y" Axes are 197 FPM (60 MPM); "Z" axis is 72 FPM (22 MPM).Axes positioning by: AC Brushless motors and YASKAWA drives; high precision ball screw drive system in "X", "Y". "Z" Axes;All axes ride on prismatic guideways & sliding blocks. -- Worktable:(6) "TV" Tubeless mobile support rails, (2) vacuum pods per rail; (4) pneumatic lifter rails for heavy panels.(6) Pneumatic pop-up backstops, (6) pneumatic pop-up front stops; (2) pneumatic pop-up side stops.LED Display positioning assistance for the support rails & vacuum pods; (2) independent working fields. -- Boring Head:3 HP (2.2 kW) motor - 4,000 RPM; (15) independent vertical spindles: (8) Spindles in "X" & (7) spindles in "Y".(6) Horizontal spindles (2 + 2) in "X" & (1 + 1) in "Y-axis".(1) X-axis grooving saw with 100 mm dia. blade - 6,000 RPM. -- Machining:(1) 10 HP (7.5 kW) Electro-spindle router with: HSK F63 Adaptor; variable speed from 1,000 - 24,000 RPM, max. torque achieved at 12,000 RPM.Static inverter for stepless speed & rapid shutdown rotation.(1) 6-Position ATC tool plate mounted on the on the machine for "on the fly" ATC; max. tool weight is 8 kG (17.6 Lbs). -- Operator & Machine Control:PC Front-End with: SCM "UNIVERSAL K2" + "Xilog Plus" + Windows "XP" Pro Operating System; 15" CRT color display, CELERON 2 GHz processor, enclosed in air-conditioned cabinet. -- Complete with:(1) 100 m³/Hr Vacuum Pump; automatic lubrication system; "BUMP STOP" safety system. -- Actual Model is SCM TECH Z30 R6

$ 22,500

SCM STARTECH CN - CNC MULTI SPINDLE DRILLINGFeatures: -- Easy Motion Work Table -- 7" Touchscreen -- (7) Independent Vertical Boring SpindlesSpecifications: -- Maximum Panel Dimensions X-Y-Z (3050mm x 800mm x 50mm), Minimum Panel Dimensions X-Y-Z (300 mm X 90 mm x 10 mm) -- Drilling/Grooving working area: 0mm x 800 mm/0mm x 800 mm ÷X-Axis Stroke: 750 mm÷X-Y maximum axis speed: 25m/Min. -- Vertical Spindles: 7 (4X-4Y one of them is shared) Horizontal Spindles: (along Y-axis): 2 (1+1) -- Horizontal Spindles: (along X axis): -- 1 Fixed Integrated Blade (cutting into direction): X Blade Diameter: 100 mm Maximum Blade Thickness: 5 mm -- Motor Power: 3 HP (2.2 kW) Spindle Rotation Speed: 3350 RPM÷Blade Rotation Speed: 4300 RPM -- Electrical Supply: 230 Volt (60 Hz) Installed Motor Power: 4.5 KVAHigh-performance numeric controlled (NC) Drilling Machine engineered for full-production woodworking shops and craftsmen. The Startech CN drilling head's seven (7) independent vertical spindles, the spindle and blade in the “X"; axis, and the possibility of drilling in the “Y"; axis make it both flexible and ideal for batch furniture productions. This machine allows the operator unparalleled flexibility for tailored products without the need of operator intervention for the worktable and machine set-up according to the panel dimensions.

$ 23,000

SCM TECH Z1 CNC MACHINING CENTER (W/ATC/BORING/"C" AXIS): -- Specifications:Working Capacity:"X" axis 120" (3,050 mm), "Y" axis 41.3" (1,050 mm), "Z" axis stroke 5.9" (150 mm), max material thickness 3.9" (100 mm). -- Positioning speed: "X" & "Y" axis is 229 FPM (70 MPM), "Z" axis is 72 FPM (22 MPM).Axes positioning by AC Brushless motors and YASKAWA drives; all axes ride on prismatic guideways & sliding blocks. -- Worktable:(6) "TV" tube-less mobile support rails, (2) vacuum pods per rail; (4) pneumatic lifter rails for heavy panels; (6) pneumatic pop-up backstops, (6) pneumatic pop-up front stops; (2) pneumatic pop-up side stops.LED display positioning assistance for the support rails & vacuum pods; (2) independent working fields; -- Boring Head:3 HP (2.2 kW) motor, 4,000 RPM; (8) Independent vertical spindles, (5) spindles in "X" & (3) spindles in "Y".(6) Horizontal spindles (2+2) in "X" & (1+1 ) in "Y" axis; (1) "X" axis grooving saw for max. 120 mm dia blade - 6,000 RPM. -- Machining:(1) 10 HP (7.5 kW) Air-cooled Electro-spindle router with HSK F63 adaptor; variable speed from 1,000 - 24,000 RPM, max. torque achieved at 12,000 RPM; static inverter for stepless speed & rapid shutdown rotation.(1) NC controlled "C" Axis for 360° Horizontal Processing.(1) 10-Position ATC rack mounted on the RH side of the machine. Max. tool weight is 8 KG (17.6 Lbs). -- Operator & Machine Control:PC front end with SCM "Xilog Plus" + Windows "7" Pro operating system; 15" CRT color display, CELERON 2 GHz processor, enclosed in air-conditioned cabinet."XILOG PLUS" offers the advantage of having simple and intuitive software • Easy-to-use: easy planning of 3D elements due to the software modules: Cabinet to create complete cabinets and furniture; Nesting for rectangular and free-form elements it also ensures reduced production time and tool paths; WD to create complete fastenings; intuitive programming due the pre-set large graphics macro library; Immediate work table set-up from 3D graphics -- Complete with:(1) 100 M³/Hr Vacuum Pump; automatic lubrication system; "BUMP STOP" safety system; Scrap conveyor. -- Actual Model is SCM TECH Z1

SCMI STARTECH/23 23-Spindle Construction Boring Machine.Specifications: -- Distance between spindles 32 mm (1.26"), Maximum drilling head distance 704 mm (27.72"), Maximum drilling depth 45 mm (1.77"). -- Panel thickness 10 - 75 mm (0.39" - 2.95"), Maximum panel width under bridge 1,000 mm (39.37"). -- Maximum panel size:270 mm(10.63") (with vertical head), 130 mm (5.12") (with horizontal head). -- Drilling head stroke 63 mm (2.48"), Tool diameter 5 - 10 mm (0.20" - 0.39"), Tool length 55 - 75 mm (2.17" - 2.95"). -- 26-1/4" x 40" x 33-1/2" H Table, 2.64 kW (3-1/2 HP) 3,390 RPM Motor.Equipped with: -- 23-Spindle Boring head (Aluminum alloy single block), Drills vertically from top & horizontally from rear. -- Manual tilt with Gas shock cylinder assist, Positive stop at 45° for boring at angle. -- 6-Position Turret depth stop. -- (2) 3" Diameter Air hold-down clamps, Foot pedal operated. -- Index pins for line boring, 15-1/4" L x 1-1/2" H Side fences.Complete with: Operation & Maintenance Manual & SHOP FOX Mobile Base with Swivel Casters. -- Dimensions: 58" x 48" x 46" H. Weight: 1,100 Lbs.

$ 4,800

SCM TOP 35 BORING MACHINE(35) Spindles on 32 mm centers, pivoting boring head, drills vertically from the top and horizontally from the rear,Specifications: -- 0° - 90° Motorized tilting of the head, can be locked at any angle between; max. panel width 1.280 mm. -- (2) 6 HP - 2,800 RPM Motor; quick boring depth setting with (6) depth stops on revolving turret, viscous damper for smooth drilling & through boring. -- Designed with: Lead screw w/veneer scale for head displacement setup.Complete with: -- Back fence w/flip stops, plus fence extension with (4) mechanical reference stops, (4) pneumatic hold-downs; 33" worktable height.

Call for Price

35 spindles (vertical/horizontal) 32mn spacing left/right fences quick release chucks 2800 rpm spindle speed 5 HP 3 Phase

SILVER SJK-21 Horizontal & Vertical Boring on 32 mm centers.(21) Spindles in line on one boring head (aluminum alloy single block), drills vertically from top & horizontally from rear. -- Features pneumatic adjustment for horizontal boring.Specifications: -- Max drill dia. is 1.38" (35 mm); Max panel thickness is 2.36" (60 mm); Table size 36" x 19.75" (914 x 502 mm). -- Length of cross fence is 102" (2,600 mm); length of aluminum table fences are 39" (1,000 mm) to the left and 28" (710 mm) to the right with flip stops.Equipped with: -- Depth stop adjustment, (2) holddown air cylinders, and foot pedal operation for clamping/drilling cycle. -- 2 HP - 3,600 RPM TEFC motor with thermal overload protection and low voltage controls.. -- Includes (12) Quick change chucks..

SILVER SJK-19T Line Boring MachineSingle line vertical boring machine with (19) spindles at 32 mm centers driven through a powerful 1.5 HP motor.Equipped with: -- Foot pedal controlled pneumatic boring cycle -- Adjustable boring feed speed -- Adjustable boring depth for fast changeover -- 2 Pneumatic cylinder clamp for solid hold-down to the material. -- 3 Meter long back fence for long line boring with flip stops -- (2) Positioning pins at both end of boring head to set up for longer line boring quickly -- Quick change chuck for fast changeover (19 pcs included)Specifications: -- No. of Spindles....................................................................................... 19 -- Distance between each spindle.............................................................. 32 mm -- Max Boring Depth .................................................................................. 60 mm (2.36") -- Working Table Size................................................................................ 800 x 500 mm (31.5" X 19.68") -- Table Height from Floor......................................................................... 780 mm (30.35") -- Max Boring Depth from Edge................................................................. 155 mm (6") -- Electric .................................................................................................. 220 V / 60 Cy / 3-Ph -- Machine Size (LxWxH) ........................................................................... 920 X 670 X 1490 mm (36.25" x 26.37" X 58.66") -- Net Weight ............................................................................................ 220 kgs. (484 Lbs)

SILVER - SJK-65: Construction & Line Boring Machine(4) Vertical Boring Heads; 21-spindle from bottom on 32 mm centers; (1) Horizontal Boring Head; (21) spindles on 32 mm center. -- 3" (75 mm) Max. drilling depth; (3) 4.0 HP - 3,450 RPM motors; pneumatic-hydraulic drill head advance with: Speed control with working speed or (0 - 15) cycles per min.; head height adjustment with: Mechanical digital readout; 51" x 37" working capacity. -- Equipped with: (2) Pneumatic holddown clamps; pneumatic foot pedal control.

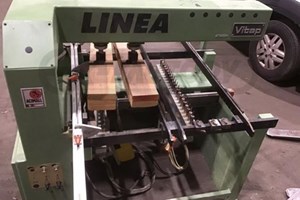

VITAP LINEA 42 Line Boring SystemSpecifications: -- (2) Drill heads of (21) spindles ea., drills from bottom up, ea. support with 2 HP motor and (21) spindle boring block w/panel support mounted on top; -- Drills panels from 100 - 3,000 mm in length, and 100 - 950 mm in width. Complete with: -- Digital readouts for boring blocks, 2,000 mm bar scale fence with (5) adjustable flip stops. -- (2) Moveable overhead pneumatic holddown cylinders, foot pedal for clamping & boring cycle.

Call for Price

Vitap Forma Boring Machine 21 Vertical Spindles 21 Horizontal Spindles Approx $1000 worth of carbide bits DUAL LINE machine and there are (2) vertical lines of 21 spindles each for a total of 42 ...... PLUS an additional single line of 21 horizontal spindles!

VITAP ALFA - 27: Construction/Line Borer27-Spindle boring head on 32 mm centers; drills vertically from bottom-up and head rotates to horizontal position for edge boring; head rotation is pneumatic with switch control. -- 2-3/4" Max. drilling depth; 2-1/2 HP - 2,800 RPM motor; pneumatic drill head advance with speed control; head height adjustment with mechanical digital readout; 34" x 20" table size; max. workpiece width 31-1/2". -- Equipped with: Left- & right-side fences for construction boring; (2) pneumatic holddown clamps; 118" line boring fence w/flip stops; pneumatic foot pedal control; magnetic starter; overload protection.

$ 41,200

WEEKE - BHX 050: CNC Machining Center (Vertical) -- Specifications Flexible "Vertical" Machining Center: Uses less than 5 sq/m of valuable floor space; includes an innovative Panel Handling System. -- Working CapacityMax. workable part size for: "X" Axis: 98.4" (2,500 mm); "Y" axis 33.4" (850 mm); max. part thickness 2.4" (60 mm).Min. worktable part size for: "X" Axis: 7.8" (200 mm); "Y" axis 2.7" (70 mm); min. part thickness of 0.47" (12 mm). - Automatic infeed & outfeed from the LH or RH side. -- Positioning Speed"BHX 050" Reaches movement speeds of: 164 FPM (50 MPM) in "X" & "Y" axes; 50 FPM (15 MPM) in "Z" axis with total safety; provides an unmatched working capacity. -- Boring Unit(1) 3 HP (2.3 kW) Variable speed from: 1,500 - 7,500 RPM Motor; (8) independent vertical spindles with: (4) Spindles in "X" axis; (4) spindles in "Y" axis.(3) Horizontal Spindles with: (1 + 1) in "X axis; (1) spindle in "Y" axis.Boring block has: QUICK-CHANGE Spindle system. -- Operator & Machine ControlWEEKE "POWER CONTROL" + Windows + WoodWOP 6.0 + Operating System; "IntelCore 2 DUO" Processor.17" TFT Monitor; international keyboard; soft touch keypad; industrial mouse; RS-232 serial ports; USB ports; (1) 1.44 MB floppy disk drive; (1) CD RW drive; modem; Ethernet connection.Real-time multitask processing; programs can be transferred via diskette or downloading by wire is possible. -- Complete with:Pneumatic part clamping devices; sound enclosure; complete set of safety devices.Options include:● (1) "X" Axis grooving saw: 9,000 RPM; saw blade dia. 100 mm.● (1) 5 HP (3.6 kW) Electrospindle router with: Hydraulic "QUICK-CHANGE" tool system; "ETP 25" tool holders; variable speed from 6,000 - 18,000 RPM. ● Voltage transformer: 600 Volts operation. -- Actual Model: WEEKE BHX 050.

.gif)