LUMBERMENOnline.com’s Latest Industry News & Articles

Submit your company’s latest news or articleDear NHLA Members and Industry Friends:

The Hardwood Federation is working with the National Association of Manufacturers (NAM) and the Family Business Estate Tax Coalition (FBETC) to deliver a joint sign-on letter (below) to Dept. of Treasury Secretary Jack Lew urging the withdrawal of new estate tax regulations recently released by Treasury. These proposed regulations would severely limit the ability of many business owners to pass their companies down from one generation to the next by restricting the use of minority valuation discounts for estate tax purposes. The Hardwood Federation fact sheet on this issue is attached HERE.

This letter is open to all family-owned businesses and corporations, businesses, industry and trade associations, state and local chambers and allied organizations. If you are interested in signing your family owned company onto the letter, please do so at the following link:

http://namissvr.nam.org/minisites/securesignup/letter.aspx?ID=113 <- COPY THIS LINK INTO YOUR BROWSER

Please also feel free to share this opportunity with your peers that have family owned business as well as other wood products associations you may be involved with. The Hardwood Federation is unable to sign on other organization and business so be aware that those interested must sign on themselves through the link above.

The deadline to sign on to the letter is Monday, September 26, 2016 by 5:00 EST.

This was a key issue for the 2016 Hardwood Federation Fly-In which concluded Thursday morning. The discussions were timely given that many members of Congress are unaware of these proposed regulations and the tremendously detrimental impact they will have on family owned businesses. The Federation hopes to have a tremendous representation from the wood products industry on this letter.

Thank you for your assistance on this very important issue.

Questions on the issue, should be directed to Dana Cole at [email protected].

Introducing "The Cub" 9" Benchtop Bandsaw, Grizzly's first addition to our benchtop series of portable home shop machines. We designed this machine with many of our industrial elements from our bestselling 14" models, and added some industry-first features for a benchtop bandsaw like the stout carrying handle, upper and lower ball bearing blade guides, and LED light. Metal doors and a 4" dust port with a 2-1/4" reducer for shop vacuums add to the list of impressive features this little bear offers. The all-aluminum fence and built-in table scale make this a great addition to any shop - small or large.

MACHINE HIGHLIGHTS (see Machine Data Sheet for full specifications)

• 1/3 HP, 120V, single-phase induction motor.

• Features rack-and-pinion table tilt from 0°–45°, an extruded aluminum fence with camlock

handle, and LED light.

• Quick-release blade tension and ball-bearing blade guides.

• Accepts 62" long blades 1/8" to 3/8" wide and is capable of 35/8" maximum cutting height.

• Made in an ISO 9001 Factory

• Weighs approximately 42 lbs.

The Model G0803 is available at an introductory price of $189.95 (valid through 12/31/16); regular

price is $230.00. It is covered by a one-year warranty. For more information call 1-800-523-4777

or visit www.grizzly.com.

PRS Group Inc. is proud to announce their newest product, NAIL IT Pallet Assembly Jigs. These economical, simple and productive nailing fixtures add flexibility and ergonomics to hand nailing pallets. NAIL IT Pallet Assembly Jigs produce pallets from 24” x 24” up to 52” x 52” with quick and easy changeover. These fixtures are built to handle 2, 3 and 4 stringer pallets, plus wing types. Standard with 8 board stops and 6 stringer stops. Constructed from structural steel, Pallet Assembly Jigs will work with both new and recycled lumber. For more information on NAIL IT Jigs call PRS today at (217) 291-0009.

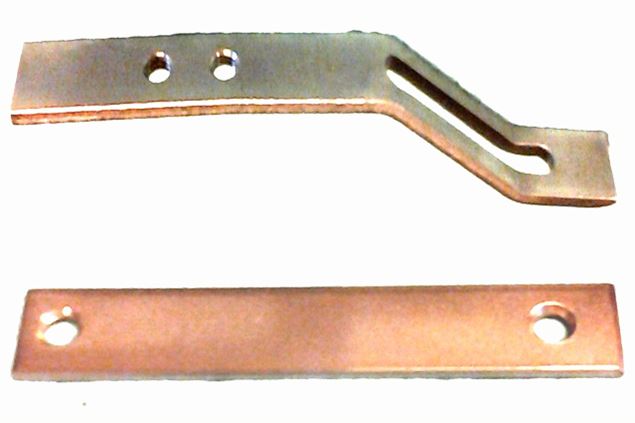

Jones Saw Tools has introduced it's new Stainless Steel Tooth Stop and Stainless Steel Tooth Rest for the Jones Longhorn Saw Grinder. These will also fit the Hanchett Jockey Grinder, and proper mounting bolts and screws are provided with each part.

The Stainless Steel Tooth Stop and Tooth Rest are just two of several innovations that make the new, full size Longhorn Saw Grinder the preferred choice for sharpening your head saw. Stainless Steel is much tougher and more wear resistant than conventional steels now used on these two items.

The Jones Tooth Stop will last about two times longer than current tooth stops. In addition, the Jones Tooth Rest is also reversible, allowing it to be turned over so both sides can be utilized before being replaced. It will last about four times longer than current models. Not only does this greatly reduce the replacement cost of these two items, but it also reduces the down time required to replace them.

Fecon’s fast cutting Samurai Knife mulching tool now has a wider edge for even greater performance. The new Samurai tool provides over 14% more cutting width on its uniquely tapered edges that quickly slice as they cut through wood and brush. A vertical splitting element is also maintained in the durable forged body to help material efficiently flow as it is being cut. While the Samurai edge can be sharpened it has a self-shaping characteristic to maximize cutting efficiency with less maintenance. The newly improved dual edge Samurai tool is available in Fecon mulchers equipped with either smooth drum FGT or depth controlled DCR rotors.

About Fecon - Fecon, Inc. was established in 1992 near Cincinnati, Ohio. Fecon’s Bull Hog is currently the #1 selling forestry mulcher. Fecon also provides track carriers and other equipment for vegetation management, geothermal, seismic, and wood to energy biomass industries.

If you would like more information about Fecon or the DCR please call Courtney Haag at 513-696-4430 or e-mail at [email protected]

Automated Biomass System’s newest member to the AutoSplit family is the AS-390. Utilizing a ½ thick plate steel frame with integrated hydraulic tank and a 12 HP Honda GX-390 engine to create a machine with all the technology and durability of its Big Brother the AS-630 HD at a price tag that’s aimed at the home or small woodlot owner.

This unit features the same 4” cylinder, 23” maximum log diameter chamber, uses the same wedges as the entire Autosplit family. Plus the AS-390 also incorporates our revolutionary hands free automatic log pullback system to increase throughput while simplifying operation. This proven system produces uniform sized wood that stacks better, dries better and sells better.

This unit pairs to an optional Fines separator with our integrated Pass Thru Technology. Combine that with the optional Log lift and extra 3, 4, and 5-way wedge, and you have an industrial grade, versatile splitter at a fraction of the cost of the competition

The AS-390 utilizes our AutoSplit technology to produce up to one full cord of evenly split firewood per hour with minimal handling. Powered by the legendary Honda GX-390 12 HP engine and advanced hydraulics including a robust 4” bore 3” rod cylinder, this machine will make the arduous task of splitting firewood a more enjoyable and productive experience.

Based off a frame constructed out of ½” thick plate steel, this machine is built to withstand the abuses which inevitably occur while splitting firewood. Our unique wedge, constructed out of high strength alloy steel, allows for even sized firewood regardless of block diameter. When splitting large blocks up to 23” in diameter, the machine automatically feeds the block through the wedge until it has been split. When splitting smaller pieces, the operator can keep feeding as many blocks into the chamber as possible while the pusher plate keeps feeding them through.

Have twisted and crooked wood? No problem for the AS-390 as it will shear through the knots branches and twists to create even sized stackable pieces.

Morbark, LLC, has added a smaller flail option to its product line, the 223 Stand-alone Flail. Easy to transport, the model is efficient and robust for in-woods chipping applications.

“Through extensive market research that included design input from customers, we saw the need for a smaller, more affordable option that gives contractors the versatility of being able to produce clean chips or transition back to producing a fuel chip with relative ease, which is key in an ever-changing chip market” said Michael Stanton, Morbark Industrial Products Business Unit Director. “The Morbark 223 Flail gives contractors the power of our larger equipment with the portability of a smaller unit to serve diverse markets.”

The 223 Flail is designed to work in conjunction with chippers like the Morbark 23 Chiparvestor®, the 40/36 Whole Tree Drum Chipper or similar machines. With a large 56” x 23” infeed opening, the 223 Flail accepts logs up to 23” in diameter at a feed rate from 70-150 feet per minute. The Morbark Integrated Control System allows for fine adjustment of feed rate and flail drum speed so that bark removal is maximized and removal of “good” fiber is minimized for superior end products.

With the widest flailing chamber in the market, the 223 reduces hassle while feeding and allows for additional stems to be fed during operation. The most ground clearance and debris plow pushing power in the industry eliminates the potential of plugging, while four independent stabilizers level the machine on nearly any type of jobsite.

Other key features of the 223 flail include the dual horizontal segmented flail drums — each equipped with eight flail chain rods — which are more durable and provide longer wear life than traditional tubular style drums used by competitors, and a large work/inspection area for easy access to engine and hydraulic components, for easier maintenance and reduced costs.

Morbark has produced aggressive, highly productive stand-alone flails and combination flail Chiparvestors since 1990. Morbark Flails are designed to provide unmatched flexibility in controlling individual variable flail drum speeds, feed rate and other parameters, while meeting the challenges of varying timber, climate, species and conditions.

The new Morbark 223 Flail makes its debut at the Mid-South Forestry Equipment Show on August 26-27 in Starkville, Miss., shown by Morbark dealer B&G Equipment.

Wood-Mizer LLC, the world’s leading portable sawmill manufacturer, introduces three new log splitters to their diverse line of wood processing equipment. Manufactured in the USA, Wood-Mizer’s new log splitter line is designed for farm operations, small businesses, and commercial wood splitting companies.

Offering three portable, heavy-duty log splitter models, the Wood-Mizer FS300, FS350, and FS500 Log Splitters offer many unique features to the log and wood splitting market. Portability, bi-directional splitting, uniform firewood production, and an efficient and ergonomic operator location make Wood-Mizer Log Splitters a profitable investment for firewood producers. “Throughout our history, Wood-Mizer has been committed to providing the best quality equipment to process logs into marketable wood products,” said Wood-Mizer COO Darryl Floyd. “The introduction of our log splitting product line now offers firewood producers a safe and efficient product backed by the high-quality and service you expect from Wood-Mizer.”

FS300 Log Splitter

• One-directional splitting

• Honda gas 390cc engine

• 29 ton splitting force

• 22 GPM, 2-stage hydraulic pump

• 1 full cord/hour production

FS350 Log Splitter

• Bi-directional splitting

• Honda gas 390cc engine

• 29 ton splitting force

• 22 GPM, 2-stage hydraulic pump

• Up to 2 full cords/hour production

FS500 Log Splitter

• Bi-directional splitting

• Honda gas 630cc engine

• 42 ton splitting force

• 28 GPM, 2-stage hydraulic pump

• Up to 3 full cords/hour production

The Wood-Mizer FS300, FS350, and FS500 Log Splitters are now available to order. Visit http://www.woodmizer.com/logsplitters or call 800.553.0182 for more information.

About Wood-Mizer

Since 1982, Wood-Mizer has earned the reputation as the world’s largest manufacturer of portable band sawmills with tens of thousands of bandmills sold around the globe. Today, Wood-Mizer offers an extensive line of portable sawmills, industrial headrigs, resaws, edgers, kilns, log splitters, material handling equipment, bandsaw blades and blade maintenance equipment for woodworking hobbyists and forestry professionals all over the world. For nearly 35 years, Wood-Mizer has provided top quality wood processing equipment and exceptional customer service for people who want the freedom of sawing their own lumber for projects or production. For more information about Wood-Mizer, call 800.553.0182 or visit www.woodmizer.com.

Lake States Lumber Association Education is offering a Sawing, Edging and Trimming Class on Friday, Oct. 14, 2016. This one-day workshop will cover the basics of NHLA grading rules, sawing for recovery, and edging and trimming requirements. Bottom dollar issues of upgrade and increased recovery will be emphasized. For complete information, including the class schedule, location, instructors and online registration, visit www.lsla.com

Fecon Inc is proud to announce Fecon UK Ltd. as an authorized dealer. Fecon UK will cover the United Kingdom and Ireland and sell the complete line of Fecon FTX Tracked Carriers, Rubber Tire Tractors, Bull Hog Forestry Mulchers and Forestry Attachments. With plans for a network of service agents across the UK and a hire/demonstrator fleet available for customers and sub-dealers, Fecon is confident in Fecon UK Ltd’s success.

“We at Fecon are excited to partner with Justin Kingwell and his staff, in the UK market. With over 25 years of mulching experience; their knowledge of the marketplace, and the industry, will be instrumental in developing the Fecon brand.” Matt Warfel, Fecon Regional Manager

About Fecon - Fecon, Inc. was established in 1992 near Cincinnati, Ohio. Fecon’s Bull Hog is currently the #1 selling forestry mulcher. Fecon also provides track carriers and other equipment for vegetation management, geothermal, seismic, and wood to energy biomass industries.

###

If you would like more information about Fecon or Fecon UK, Ltd. please call Courtney Haag at 513-696-4430 or e-mail at [email protected].

Fecon UK, Ltd. - http://www.fecon.co.uk/

LPS Equipment & Acquisition Company announces they will be conducting monthly online ONLY consignment and inventory liquidation sales in conjunction with Associated Auction & Liquidation Company. The monthly sale will give the industry an alternative way to liquidate excess equipment in a timely and expected manner. LPS will ensure the auction has a full wide-spread list of inventory every month by including their own diverse inventory varying from fully rebuilt equipment, hard to find items, and as-is trade-ins.

Auctions will start in August and will target a regular schedule near the end of each calendar month, with the first one beginning August 24th starting 9 AM CST through August 31st with Lots closing at 2 PM CST. Information on the upcoming auctions will be updated daily for the next scheduled auction at www.LPSbid.com.

The auction set up is designed to benefit the buyer and seller in many ways. If you’re looking to sell equipment, you’re welcome and encouraged to enter one item or a small line up and never have to move the equipment prior to the sale being final. Buyers can expect high-quality equipment, low reserves, and a secure online bidding process.

Whether you’re looking to sell a few items or purchase equipment without leaving the office, bookmark www.LPSbid.com on your browser for the next upcoming sale! For more information call LPS Equipment at 800-598-3651!

European bandsaw producer Metamob has launched a new venture in North America with the annoucement of an exclusive distribution agreement with Union Grove Saw & Knife. Under the terms of this agreement, Union Grove will now handle all sales and service of bandsaw blades produced by Metamob in the U.S.. Metamob will stock an inventory of commonly used sizes at Union Grove for prompt delivery to the local markets. Future plans call for the production of bandsaw blades in North Carolina under the newly formed partnership.

Istvan Hutton co-founded Metamob in 1994 to meet demand for woodworking tools in their local markets. In 1997 the company started producing various configurations of extremely high quality bandsaw and frame saw blades at compeitive prices. Professional sharpening services followed in the same year. Today production is extremely focused on the niche market of wide and narrow bandsaw blades for the sawmill industry.

In May 2007, METAMOB obtained the quality management certificate according to ISO 9001 and in 2010 received ISO 14001 certification. The company maintains a continuous process of research and innovation to offer the best possible products while working diligently to establish long-term partnering relationships. The company is very unique in that the professional development of customers and employees alike is one of their most important business goals.

Hutton states, ”We take a lot of pride as a company in the fact that that we have a unique ability to discern customer needs and provide a customized solution for the specific application at a compeitive price and timely manner. The company has developed special software applications in-house that enable the engineering department to optimize bandsaw blades for exact machinery and cutting parameters. All blade designs are completed using CAD and further produced on CNC equipment produced by Iseli in Switzerland.”

Metamob has the largest installed base of Iseli machines, world reknown as the premuim basis for bandsaw production globally. Products are wet ground with exacting tolerances on this highly specialized equipment. ”To complement this production a CNC setting machine was developed in house for spring set tooth products to a precision of +/-0.01 mm which contributes to a better surface finish in the cutting process,” Hutton added.

Hutton expressed, ”Customers of Metamob can expect to receive excellent cutting results from blades fully optimized for the specifc operation and machinery being used. In addition, they have a flexible production system which enables prompt delivery of specials. This, in conjunction with the inventory of standard sizes warehoused at the Union Grove, NC, facility, allow us to now be perfectly positioned for the North American markets.”

To further support their expansion into North America, Metamob is moving, in the fall of 2016,into a new production facility and will significantly increase capacity. New equipment is being installed and additional factory automation is being implemented. These advancements will allow it to maintain competitive prices and reasonable delivery times. Long-term plans are to manufacture in the U.S..

Union Grove

Union Grove Saw and Knife, Inc. was founded in 1983 by Ed Bissell with a strong desire to become a regional tool company known for exceptional service and quality. Today it services over 300 customers. Most importantly the company still services and maintains its original 10 accounts. In 2016 a new management team was established with Anthony DeHart leading the expansion efforts.

Union Grove has built a reputation for being competitively priced while delivering a consistently high standard of workmanship and quality products, and maintaining timely deliveries in ever changing market conditions.

The company now has over 125 pieces of specialized equipment all dedicated to servicing cutting tools. This equipment along with a highly-trained staff provides the highest level of craftsmanship and tooling specifications within the industry. A new managment team combined with the core employees within its organization have vast experience in not only the production and design of cutting tools, but most importantly the disciplines surrounding the effective selection, utilization and maintenance for the lowest possible total cost.

Union Grove recognizes that in order to provide customers with the highest possible product quality for every cutting application, unique partnerships with wolrd-class producers have to be established. This relationship with Metamob exemplifies this type of partnering relationship and is the first of many to come.

Our goal is to form long-term partnering relationships with customers who seek to gain a competitive advantage through better management of their cutting tool resources. We are committed to helping you achieve better management and efficiency of your tooling which results in a lower total cost of ownership and utilization.

Products

Union Grove offers the complete range of Metamob products from its base of operations in North Carolina. Standard bandsaw blades trademarked METABLADE are specifically designed for cutting logs in various conditions. Known for high durability and easy maintenance due to the level and tensioning provided in production. METABLADE is the leading product for quality and cost ratio.

For demainding applications, the highest durability and precision cutting applications, the product lines of METAPREMIUM and METAPRECISION are offered. These blades are produced from the highest quality raw materials under extremely controlled conditons and are capabale of performing at the highest level of any bandsaw blade produced globally.

All configurations are available with equal or variable pitch-tooth forms in any shape requested. New tooth shapes to increase stability, offer faster speeds and ensure sawdust evacutation are available. Sizes range from 4” wide thru 14” in width in thickness from .042” thru .083” incrementally.

METGOLD bandsaw blades are offered for high stability in portable bandsaw mills. Sizes range from 1-1/4” wide thru 3” width in thickness from .035” thru .049” incrementally. Teeth are set and hardened to 58/61 HrC in various pitch and hook angles.

#####

For more information on Metamob or Union Grove, contact Anthony DeHart at 828-217-3739 or [email protected]. Additional details can also be found at www.sawandknife.com or www.metamob.ro

.gif)