LUMBERMENOnline.com’s Latest Industry News & Articles

Submit your company’s latest news or articleAfter 25 years of stamping metal fasteners for the wooden pallet industry, PRS now manufactures FIVESTAR Log Plates. These plates are designed to protect logs from splitting as they dry between harvest and the mill. They are economically aimed to maximize profit of your inventory. The innovative design features a high strength, low alloy steel plates in a variety of sizes to fit various needs. These log plates are easily attachable and create maximum holding power. The 20 gauge, galvanized steel plates are strong and rust free! Just like the PRS FIVESTAR Pallet Plates, they ensure the highest quality - plate after plate, box after box, and skid after skid. For more information regarding this new product, head to PRS’ website at www.prsgroupinc.com or call them at (217)291-0009.

Wood-Mizer LLC, the world’s leading portable sawmill manufacturer, introduces the groundbreaking Vortex® sawdust-removal bandsaw blade. Available now in North America, Wood-Mizer’s new Vortex® blade is engineered for pallet producers who need boards as free from excess sawdust as possible.

Developed by long-time, hands-on Wood-Mizer Blades Specialist Chris Vogel, the Vortex® blade removes dust while sawing in order to minimize or eliminate the need for sawdust removal after the lumber is processed. This extremely unique blade profile has generated positive results in high-production pallet factory tests. Pallet producer, Jeff Coomer of Indiana-based Coomer & Sons Sawmill, tested the blade and says, “The Vortex blade was getting 98 to 99% of the dust off, so it was impressive on how much dust it took off [compared to] a typical saw blade.” Additionally, Paul Smith of Smith Sawmill Service in Texas says, “The new Vortex blade does a great job of getting the sawdust off the wood. It’s going to be an asset for companies trying to produce a clean pallet.”

The Wood-Mizer Vortex® blade is now available to order in .042 x 1 ¼ at any length. Call 800.522.5760 or visit www.woodmizer.com/vortex for more information.

Offering more than 60 basic blade profiles and an extensive array of combinations based on tooth profile, width, thickness, tooth set and tooth spacing, Wood-Mizer offers blades for any type of sawing application from softwoods to hardwoods. Order online at www.woodmizer.com/blades.

Ellison Sales, Incorporated, of Portland, Oregon, North America’s leading provider of aftermarket parts and complete service for hogs built by Montgomery Industries, Streamline lasers as well as equipment brokerage and consulting services is proud to unveil its newly redesigned interactive website. Founded in 1961, Ellison Sales has built a reputation on providing honest service and superior products where the customer comes before profit. The new website is an extension of that commitment to service and quality. Created by the team at LumbermenOnline.com, the sister company of LUMBERMEN’S Equipment Digest www.ellisonsales.com features improved graphic interface, easy to use navigation and up to date inventory management system. In addition visitors will find a complete line of long lasting parts, lasers for all applications, MDI Metal Detectors plus interactive contact options, multiple images, video and more. See what Ellison Sales can do for you today by visiting www.ellisonsales.com.

Grizzly Industrial is excited to announce a new 14" Sliding Tablesaw!

This state-of-the-art sliding table saw is designed to handle large sheet goods with push-button ease. Blade speed, height adjustment, blade tilt, and scoring blade alignment are all controlled from the digital console, simplifying on the fly changes during the most exacting jobs. The saw accommodates both 12" and 14" blades and is powered by a 10 HP main motor, joined by a 1 HP scoring blade motor that spins at 8000 RPM to virtually eliminate tearout and produce clean cuts every time. The sliding table glides along precision bearing rollers to provide smooth operations, and with crosscut capabilities of 126", you'll be able to handle the biggest jobs.

Fecon is proud to announce their new mobile balancing systems, the FMB-100 and FMB-200, for your forestry mulcher. The mobile balancing systems can work on any make or model of forestry mulcher.

The Fecon FMB100 is an extremely cost-effective solution to the damaging vibration caused by rotor imbalance. The FMB-100 mobile balancer tells you how out-of-balance the rotor is (magnitude), and where adjustments are needed (phase/angle). Once balanced, the difference is amazing.

The Fecon FMB-200 is a state-of-the-art dynamic balancer with full spectral analysis. Not only can it walk you through the balancing process, indicating where to add weight and how much, it also analyzes all frequencies to help troubleshoot vibrations that are not from rotor imbalance. It can tell the difference between a rotor imbalance, a failing bearing and other issues that cause damaging vibration.

About Fecon - Fecon, Inc. was established in 1992 near Cincinnati, Ohio. Fecon’s Bull Hog is currently the #1 selling forestry mulcher. Fecon also provides track carriers and other equipment for vegetation management, geothermal, seismic, and wood to energy biomass industries.

###

If you would like more information about Fecon or the mobile balancing sytems please call Courtney Shafer at 513-696-4430 or e-mail at [email protected]

Cooper Machine is excited to announce that we are now offering MIT's line of Pallet Equipment including a Carousel Block Cutter, Chamfering Machine and Pallet Trimmer. More information on this equipment can be found on our website at http://www.coopermachine.com/Sawmill-Equipment/59/PalletMachinery.

Cooper Machine also has great options for sawmills looking to produce pallet stock including an Overhead Scragg with Vertical Edgers, Yield Champ (Sharp Chain Scragg with Cant Edger), Cutup Systems, Unscramblers, Edgers, Automated Cant Trimmers, Slab Recovery Systems/Resaws, Handling Equipment, Sorting Systems and Kilns.

We are also honored to now be a member of the National Wooden Pallet and Container Association. We're looking forward to seeing everyone in Tucson next Spring.

Baker Products have innovated a new log to lumber system from their pre-existing equipment, in a new layout to lower labor, increase production, and provide maximum yield. The system uses 2 employees, and begins with one operating the Baker BP Dominator Sawmill. This Sawmill is equipped with hydraulic kickers in the outfeed roll case to either, kick timbers into the automated Baker Timber Stacker, or to kick waney edge boards to the Band Edger’s feeding deck. From the Band Edger’s feeding deck, an employee grabs a waney edge board and feeds it into the Baker Band Edger, to eliminate its waney/barky edges. On the outfeed side of the Edger, a hydraulic table top lifts the edged board and two edging strips, sliding them onto a belted conveyor. This conveyor delivers the material back to the employee who feeds the edger. He then stacks and bundles the boards and edging strips. The core of the logs, AKA timbers, that are transferred into the automated Baker Timber Stacker are stacked into a bundle, banded, and forklifted to their designated area. In the end, you have bundled timbers, bundled boards, bundled edging strips, and bundled slabs, giving you your most maximum yield out of your log and lowest labor cost.

Baker Products is proud to introduce their newest partner machine, the Wood Wizz. This machine is designed to surface and finish slabs, burls, tabletops, and even recycled timber. The machine is ideal for woodworkers who want to add value to their material and produce a perfect finish without any tear, ridging, or burn marks.

The Wood Wizz is powered by a variable speed 3-HP, motor and runs on a Z axis. It includes a large 5” (125 mm) cutter, 10 square cutter inserts, speed controller, two inverters, sanding disk with pads & sand paper, dust tower, dust hosing and fittings. The machine is equipped with a variable speed and power feed control box, with controls on the gantry, and also includes edging/joining cutter to combine two or more pieces of material, flawlessly.

Rustic wood table tops and wide slabs can produce high margins and the Wood Wizz, from Baker Products allows you to economically put a planer smooth finish on all types of slab, timber or beams.

Introducing the new Wood-Mizer FS500 Log Splitter! Featuring 29 tons of brute wood splitting force, the FS500 splits wood in both directions and produces up to two cords of firewood an hour with a 4.5 second cycle time. Fully-loaded with a heavy-duty trailer package, 2-stage hydraulic pump, oil cooler, log lift, and optional remote start, this mid-size splitter is equipped with a 3-way wedge and perfect for bundle wood and firewood businesses looking to maximize efficiency and productivity. Wood-Mizer Log Splitters are engineered for performance and built in the USA by the world leader in portable sawmills for nearly 35 years. Call 800.553.0182 or visit www.woodmizer.com/logsplitters for more information.

PRS held an Open House event April 29th- 30th at their Jacksonville, IL facility. This event hosted companies from different states and countries to see demonstrations of PRS machinery and the CAPE Mach 2 Nailing Line. PRS displayed some of their equipment including the Optimax 2016, Prosaw Band Dismantler, Stringer-Mate Stringer Splicer, and more. The CAPE Mach 2 was also operating along with a CAPE technician on-hand to discuss the complete product line. This event drew interest for customers with a variety of machinery needs. Be on the look-out for another potential open house this fall!

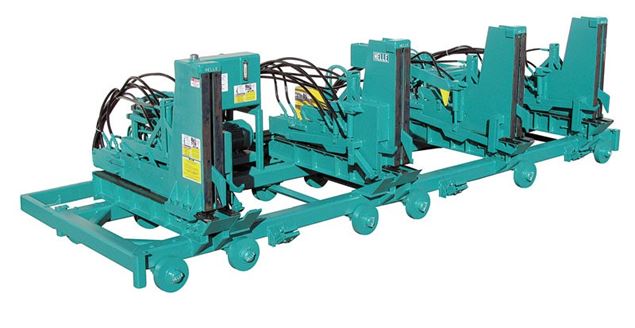

Sawmill operators are the number one engine for design improvements. Anticipating and addressing those needs has been the driving force of the Helle family and the entire staff at Sawmill Hydraulics since the creation of the hydraulic chain log turner. The new Compact Linear Positioning line of carriages from Sawmill Hydraulics is a prime example of addressing a critical need. LP technology has been unavailable to many mills due to the carriage width requirements and pricing that has put this important technology out of the grasp of many mills. To make LP technology available to every mill, Sawmill Hydraulics redesigned the way hydraulic cylinders are incorporated so the new Compact LP carriage is easily retrofit to nearly all currently running mills. This space savings also leads to tremendous savings on new mill projects as well.

In addition to the revolutionary space saving design, every Compact LP carriage is tailored to your space, your needs and your product and comes standard with proven Helle Linear Tech Touch Screen Setworks as well as optional scanning, thus eliminating the need for third party setworks. See the Compact LP carriage at outside exhibit space C7 at the 2016 Richmond EXPO and schedule your no obligation on-site assessment.

WASHINGTON – American Wood Council (AWC) Vice President, Government Affairs Sarah Dodge has issued the following statement regarding today’s passage of the “Clean Distributed Energy Grid Integration Act” (S. 2012) in the U.S. Senate. The bill included an amendment led by Sen. Susan Collins (ME) which would require the Secretaries of Energy and Agriculture and the Administrator of the Environmental Protection Agency to jointly ensure that federal policy relating to forest bioenergy: (1) is consistent across all departments and agencies; and (2) recognizes the full benefits of the use of forest biomass for energy, conservation and responsible forest management.

“AWC greatly appreciates the inclusion of Senator Collins’ biomass amendment in the Senate bill. Our member facilities use every part of the raw materials in the manufacture of wood products and to generate the energy needed to do so. In fact, almost 80 percent of the energy from AWC member facilities is generated from carbon-neutral biomass. This bill is a step in the right direction in getting our country’s public policies aligned to recognize our industry’s unique biomass use as carbon neutral and as part of the sustainable carbon cycle.

“However, we were disappointed language was left out which would facilitate product neutrality in the building energy code development process. AWC ardently believes that the Department of Energy should return to its congressionally-authorized role as a ‘technical advisor’ and not be using its position to advocate for particular products or technologies in building energy codes. These codes should be changed to remove prescriptive requirements mandating the use of particular products. They should instead be performance oriented and establish the requirements that any product, including wood, can demonstrate it meets. Wood is inherently capable of providing good thermal performance, helping to meet even the strictest energy requirements, while at the same time sequestering carbon from the air.

“We look forward to working with the conference committee and urge Congress to quickly move to reconcile House- and Senate-passed bills. AWC strongly supports the building energy code provisions in the House-passed bill and requests that any final energy legislation approved by Congress retain them to ensure all building materials have equal opportunity to contribute toward achieving building energy efficiency standards. Final legislation must also retain the Senate provisions recognizing the carbon benefits of biomass energy and requiring consistent policies across all departments and agencies, as well as the recognition of multiple green building certification systems.”

.gif)